Peugeot 308: Replacement : Front panel support

ESSENTIAL : Before any operation on the structure of a vehicle fitted with a traction battery, the vehicle must be isolated by an authorised technician.

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : Observe the precautions to be taken for the pyrotechnic components

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

CAUTION : All of the stripped surfaces must be protected by means of the approved electrolytic rezincing process .

CAUTION : The number of spot welds or weld beads required for assembling a new component must be identical to the number of spot welds or weld beads attaching the original component.

1. Information

Types of spot welds or beads using the electric arc process :

- MIG braze welding with cupro-aluminium filler used with an inert gas

- MAG welding with steel filler metal and active gas

Designation of the high strength panels :

- High strength (HSS) : High strength steel

- Very high strength (VHSS) : Very high strength steel

- Ultra high strength (UHSS) : Ultra high strength steel

N.B. : Use the products recommended by the manufacturer

.

.

2. Tooling

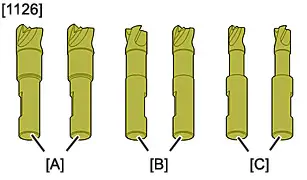

Workshop equipment : Swan’s neck drill for cutting out electric spot welds.

| Tool | Reference | Description |

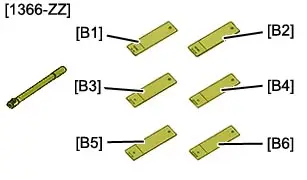

| [1366-ZZ] | Toolkit for testing electric spot welds |

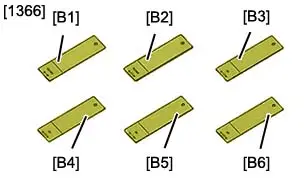

| [1366] | Samples for testing electric spot welds |

| [1126] | Set of drill bits for removing spot welds |

3. Preliminary operations

ESSENTIAL : Deactivate the pyrotechnic systems

.

.

CAUTION : Perform the operations that are required before disconnecting the ancillaries batteries

.

.

Disconnect the ancillaries batteries (Following the specific procedure

).

).

CAUTION : Either remove or protect those components which are in the repair zone and risk being damaged by the heat or the dust.

Remove :

- The front bumper

- The headlamp

- The upper crossmember

- The lower crossmember

- The cooling fan unit

Release the electrical harnesses.

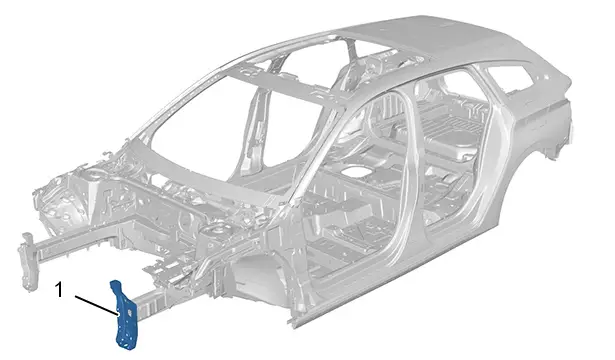

4. Location : Replacement part

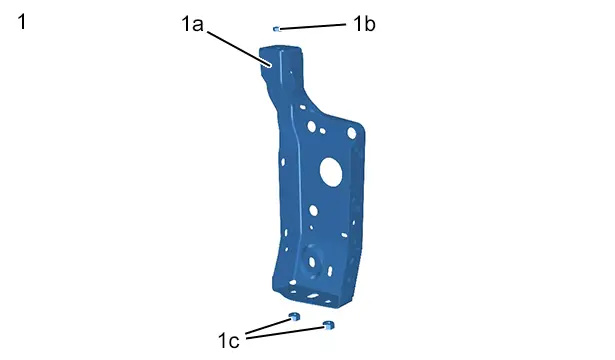

| Identification | Description |

| (1) | Front panel support |

5. Identification of the replacement part

5.1. Composition : Front panel support

| Identification | Description | Thickness | Nature/classification |

| (1) | Engine compartment front panel support assembly | - | - |

| (1a) | Front panel support | 2,00 mm | High strength (HSS) |

| (1b) | Welded nut | 6 x 100 mm | - |

| (1c) | Welded nuts | 8 x 125 mm | - |

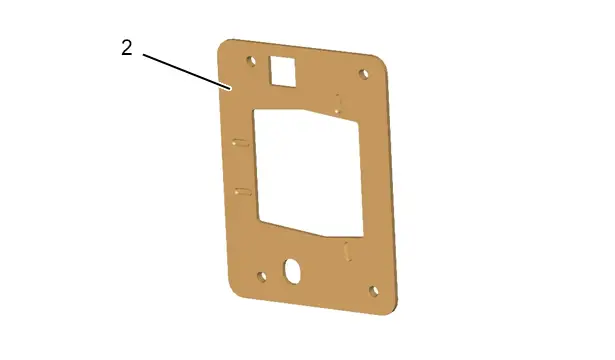

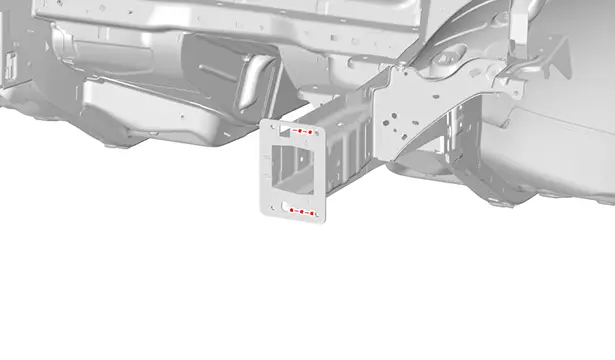

5.2. Identification of the parts adjacent to the replacement part

| Identification | Description | thicknesses | Nature/classification |

| (2) | Front impact absorber support | 3,00 mm | Very high strength (VHSS) |

CAUTION : Take into account the difference in thickness of the parts when adjusting the welding station.

6. Replacement part preparation

CAUTION : When cleaning the mating edges, use scouring wheels only to avoid damaging the anticorrosion protection.

Prepare the mating edges and protect them using a weldable primer (index "C7").

N.B. : Apply the weldable primer on the internal faces of the panels to be welded.

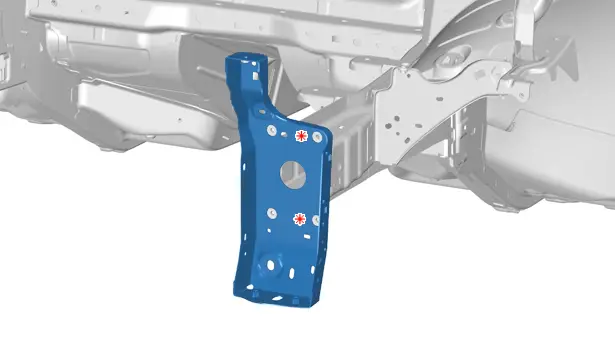

7. Cutting of the part on the body

Cut out the spot welds .

Remove the front panel support.

8. Cleaning and preparation of the body

Prepare the mating edges and protect them using a weldable primer (index "C7").

N.B. : Apply the weldable primer on the internal faces of the panels to be welded.

9. Adjustment

Position :

- The front panel support

- The components for adjusting

Check :

- The fits and clearances

- The position, using one of the approved measuring systems

Clamp the part into position.

10. Welding

CAUTION : Set the welding station.

Setting of the welding station :

- Electric spot weld testing ; Using the tool [1366-ZZ]

- Samples for testing electric spot welds ; Using the tool [1366]

CAUTION : The number of spot welds or weld beads required for assembling a new component must be identical to the number of spot welds or weld beads attaching the original component.

Weld with electric spot welds.

11. Sealing protection

Apply :

- A layer of etch primer to the zones exposed

- Sealing mastic (index "A1")

12. Additional operations

Refit the electrical harnesses and reinstall all removed components.

13. Reinitialisation

ESSENTIAL : Reactivate the pyrotechnic systems

.

.

CAUTION : Perform the operations that are required after reconnecting the ancillaries batteries

.

.

Reconnect the ancillaries batteries (Following the specific procedure

).

).

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image