Peugeot 308: Cold stamped inscription : VIN in after sales

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : Observe the precautions to be taken for the pyrotechnic components

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles(observe the regulations in force in the respective country).

ESSENTIAL : All personnel working on vehicles with a fuel cell stack must have completed the STELLANTIS training courses required to work on these vehicles(observe the regulations in force in the respective country).

ESSENTIAL : Before any operation on the structure of a vehicle fitted with a traction battery, the vehicle must be disconnected electrical supply.

CAUTION : All of the stripped surfaces must be protected by means of the approved electrolytic rezincing process .

1. Legislation

CAUTION : Refer to the regulations in force in the country.

2. Cold stamping is possible in the following cases

2.1. 1st case

Replacement of the part bearing the cold stamped serial number.

Absence of the cold stamped serial number.

2.2. 2nd case

No visual access following modification not foreseen by the manufacturer.

Serial number illegible due to considerable corrosion.

Serial number concealed (Addition of products).

Signs of work in the serial number area (Symmetrical welding and grinding).

3. Information

3.1. Characteristics of the serial number

The regulatory size of the punches for cold stamping is at least 7 mm or 8 mm.

The serial number consists of 17 characters.

The serial number is always situated on the right-hand section of the vehicle.

Depending on the vehicle, the serial number may be stamped on one or two lines.

In all cases, the serial number must be cold stamped onto a structural part.

3.2. Specifications for cold stamping of the VIN in service

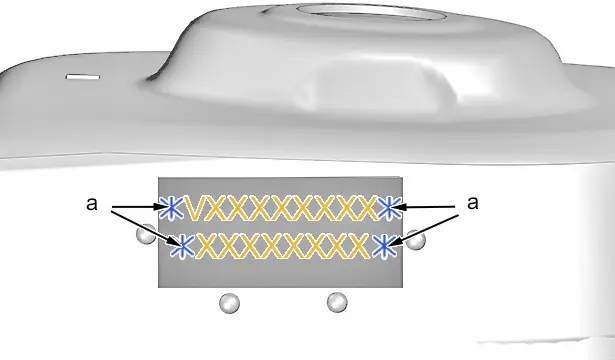

"a" : Non alphanumeric character.

When cold stamping, the marque punch mark is not compulsory.

Each line forming a serial number must have the symbol "a" at each end.

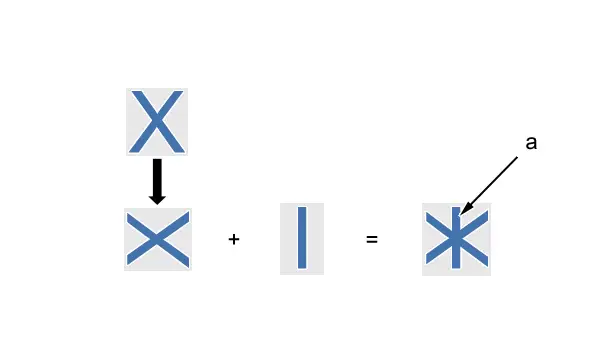

3.3. Creating the symbol

The symbol "a" is obtained by stamping the letter "X" placed horizontally, with a second stamping of the letter "I" superimposed.

The cold stamping of a serial number must be carried out by an authorised repairer of the manufacturer’s marque.

4. Tooling

Equipment :

- Kit of 7 mm stamping punches

- Mechanic’s hammer

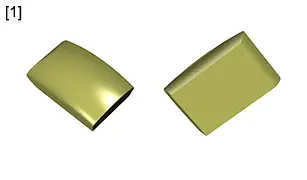

| Tool | Reference | Description |

| [1] | Coachbuilder’s dolly |

Use the dolly to prevent any distortion of the panel during stamping.

Position the dolly on the opposite face of the cold stamping area.

5. Preliminary operations

CAUTION : To prevent any corrosion, the cold stamping must be carried out before painting.

Remove the components necessary for positioning the coachbuilder’s dolly and the stamping punches.

6. Cold stamped inscription

N.B. : 2 operators are required for this operation.

7. Cold stamping of the VIN

CAUTION : The serial number is always situated on the right-hand section of the vehicle.

The serial number can be stamped close to the original one, whether underneath, above or to the side.

Refer to procedure : Location : Cold stamping of the VIN.

The stamping of the VIN may require removal of a component.

Example : Windscreen, scuttle grille, bulkhead protection, etc..

8. Protection

Apply a phosphate-print layer on the zone laid bare.

Paint as required.

9. Refitting

Refit the elements removed previously.

Example : Windscreen, scuttle grille, bulkhead protection, etc..

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image