Peugeot 308: Removing - refitting : Ancillary drive belt - Dynamic tensioner roller

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

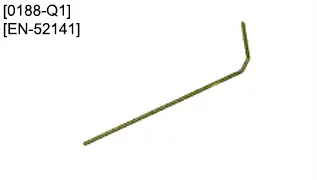

1. Tooling

| Tool | Reference | Description |

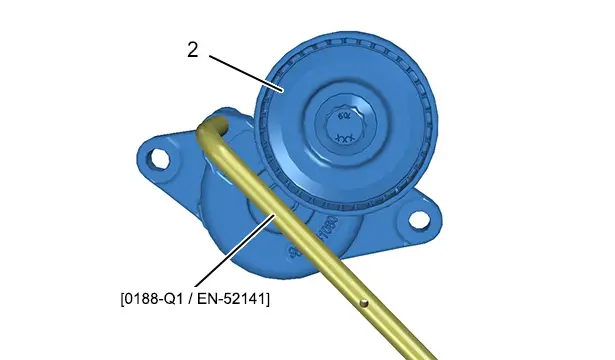

| [0188-Q1][EN-52141] | Dynamic roller tensioner setting peg |

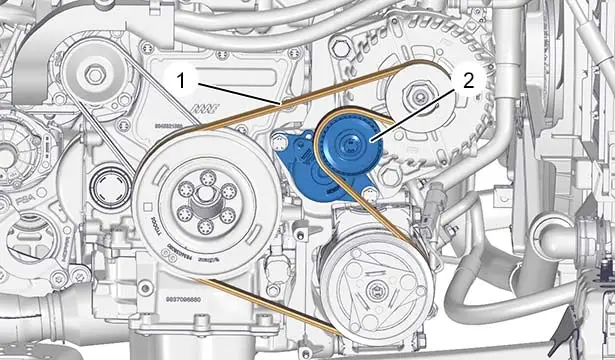

2. Identification

(1) Ancillary drive belt.

(2) Dynamic tensioner roller .

3. Ancillary drive belt

3.1. Preliminary operations

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries (depending on equipment).

Put the vehicle on a lift.

Remove :

- The front right-hand wheel

- The front right-hand mudguard

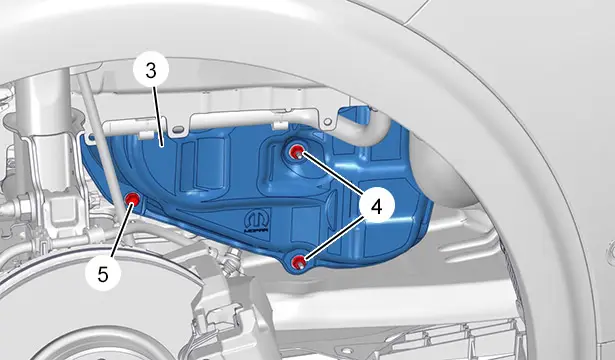

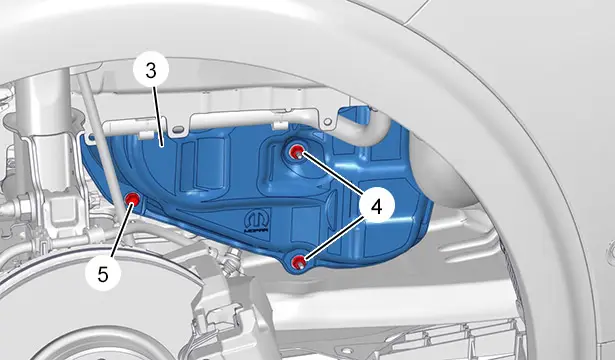

Remove :

- The bolt (5)

- The nuts (4)

- The protector (3)

3.2. Removing

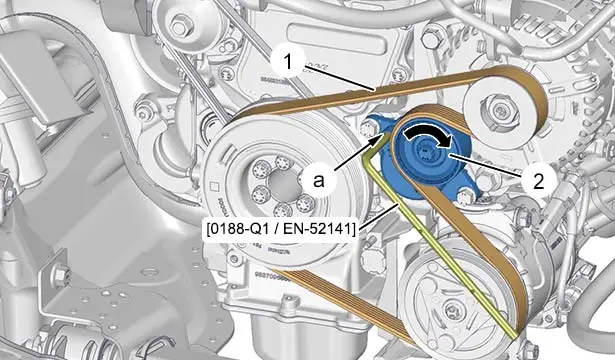

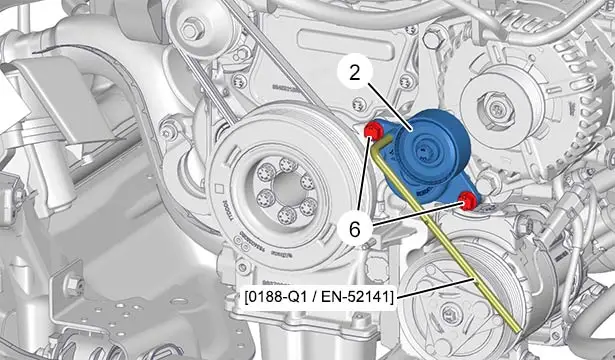

CAUTION : Observe the direction of rotation of the ancillary drive belt (1) if reusing the ancillary drive belt.

Operate the ancillary drive belt (2) (Clockwise).

Pin the dynamic tensioner roller (2) ; Using the tool [0188-Q1 / EN-52141] (at "a").

Remove the ancillary drive belt (1).

CAUTION : Check that the dynamic tensioner roller (2) rotates freely (no play and no tightness).

3.3. Refitting

CAUTION : Observe the tightening torques

.

.

Refit the ancillary drive belt (1).

CAUTION : Check that the ancillary drive belt (1) is positioned correctly in the grooves of the various pulleys.

Operate the ancillary drive belt (2) (Clockwise).

Remove the tool [0188-Q1 / EN-52141].

Turn the crankshaft 2 turn(s) in the direction of running.

3.4. Additional operations

Refit :

- The protector (3)

- The nuts (4)

- The bolt (5)

- The front right-hand mudguard

- The front right-hand wheel

- The vehicle to its wheels

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries (depending on equipment).

4. Dynamic tensioner roller

4.1. Preliminary operations

Put the vehicle on a lift.

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries (depending on equipment).

Remove :

- The front right-hand wheel

- The front right-hand mudguard

Remove :

- The bolt (5)

- The nuts (4)

- The protector (3)

- The auxiliary equipment drive belt (1)

4.2. Removing

CAUTION : Do not remove the tool [0188-Q1 / EN-52141] .

Remove :

- The 2 bolts (6)

- Dynamic tensioner roller (2) and pin [0188-Q1 / EN-52141] assembly

4.3. Refitting

CAUTION : Observe the tightening torques.

Tightening torques :

- Engine

- Wheels

N.B. : The new dynamic roller tensioner (2) is delivered with a retaining pin .

Reused dynamic tensioner roller : Refit the dynamic tensioner roller (2) and pin [0188-Q1/ EN-52141] assembly.

New dynamic tensioner roller : Refit the dynamic tensioner roller (2) and retaining pin assembly.

Refit :

- Dynamic tensioner roller (2) and pin [0188-Q1 / EN-52141] assembly

- The 2 bolts (6)

- The auxiliary equipment drive belt (1)

Operate the ancillary drive belt (2) (Clockwise).

Remove :

- The tool [0188-Q1 / EN-52141]

- The pin [0188-Q1 / EN-52141] or the retaining pin

CAUTION : Check that the ancillary drive belt (1) is positioned correctly in the grooves of the various pulleys.

Turn the crankshaft 2 turn(s) in the direction of running.

4.4. Additional operations

Refit :

- The protector (3)

- The nuts (4)

- The bolt (5)

- The front right-hand mudguard

- The front right-hand wheel

- The vehicle to its wheels

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries (depending on equipment).

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image