Peugeot 308: Organisation bulletin : Traction battery status classification

N.B. : flying doctor or electric vehicle expert : Personnel qualified for live work and equipped with a diagnostic tool for diagnosing the drive train.

1. Description of the assessment

The traction battery transportability assessment for hybrid or electric vehicles is required for the assessment of the traction battery condition, in order to determine if the hybrid or electric vehicle traction battery may be transported and in what way.

ESSENTIAL : /!\ Follow the safety regulations for hybrid and electric vehicles. The technician qualified for working at high voltage is responsible for ensuring compliance with the manufacturer’s maintenance instructions and the national regulations in force. Failure to adhere to the regulations could result in serious injury or death.

ESSENTIAL : If the traction battery or the 400 V electrical circuit is not safe, the operations to make the vehicle safe and isolation of the vehicle must be carried out by an operator authorised to work under voltage (Example : flying doctorFor France).

CAUTION : The traction battery must not be transported without carrying out the assessment and obtaining approval from technical assistance.

Always contact the Technical Assistance Centre for instructions to be applied if there is any doubt or uncertainty during the transportability assessment.

Procedure to be followed :

- /!\ : Print this form

- Carry out the traction battery transportability assessment by following the steps listed

- Note down the answer to each question unless it is explicitly stated to move on to the next step

- Scan the completed document and link it to the incident ticket in PAMIR

- Place the completed document in the transport crate

N.B. : Write down the answer to each question unless it is explicitly stated to skip the question.

2. Interpretation of assessment results

| Situation | Result obtained during the transportability assessment | Destination |

| A (NOK) | If the box "NOK" has been circled in response to one or more questions, the traction battery must be deemed unsafe and, as a minimum, arrangements must be made to transport the battery in secure packaging-Store the traction battery in the exclusion area outside the building before shipping-Before shipping, attach a completed and signed copy of this protocol to the traction battery packagingThe place of destination, repair or recycling will be decided depending on the findings ◦In the event of actual flames or smoke, call the fire services ◦Where there are flames, smoke, obvious damage (cracks) or electrolyte leakage, follow the instructions in the equipment safety data sheet ◦Do not remove the traction battery if it is in the vehicle ◦Move the vehicle to the isolation area outside the building | Recycling or repair |

| B (OK) | If the box "OK" has been circled in response to all questions: The traction battery is deemed safe and compliant for shippingRefer to the methodBefore shipping, attach a completed and signed copy of this protocol to the traction battery packaging | Overhaul(*) |

| (*) : Shipping a safe traction battery for recycling will only be considered as a last resort if there is no possibility of the battery being reconditioned | ||

3. Traction battery transportability status assessment form

| Date | - - / - - / - - - - |

| brand | - |

| Model | - |

| VIN | - |

| Identification number of the traction battery(Battery Identification Number : BIN) | 34 _ _ _ _ _ _ _ _ _ _ _ |

| Vehicle mileage (in km) | - |

| Name | Telephone | |

| Qualified assessor | _ _ _ _ _ _ _ _ _ _ _ | + _ _ _ _ _ _ _ _ _ _ _ |

| Qualified operator flying doctor, if this is not the assessor | _ _ _ _ _ _ _ _ _ _ _ | + _ _ _ _ _ _ _ _ _ _ _ |

Initial checks: Visual checks of the vehicle in the external exclusion area, traction battery is present in the vehicle

| Stage | Title | Description | Result | Destination | Action |

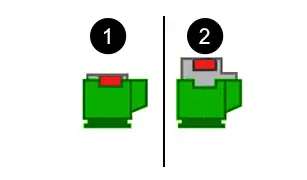

| 1 | Circuit breaker connector (e-service plug) in the open circuit position | Check the vehicle’s quick safety procedure : 1.If the circuit breaker connector (e-service plug) is in the open circuit position (Figure 2)1.1.Circle the result of step "OK"2.If it is not possible to open circuit breaker connector (e-service plug) (Figure 1)2.1.Circle the result of step "Δ"2.2.Move on to the next step after contacting an electric vehicle expert | OK / Δ | - |

|

| 2 | Red warning lamp is lit up on the instrument panel | Check the lighting of the red malfunction warning lamp for the drive train located on the instrument panel :1.If this red warning lamp comes on, a major problem has been detected on the electric drive train, which includes the traction battery1.1.Circle the result of step "Δ"2.If this red warning lamp does not come on and an airbag has not been triggeredNote2.If the pretensioners are only triggered without this warning lamp coming on, the result of the step is "Ok"2.1Circle the result of step "Ok"2.2.In this case the vehicle has only been slightly damaged and the battery is not affected by the fault2.3.Go to the next step | OK / Δ | - |

|

| 3 | FlameSmoke | Check the vehicle for flames and/or smoke1.If there are flames or smoke1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If there are no flames or smoke2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | -Recycling | An investigation is required by a PSA expert to understand the cause of the fault : Open an assistance ticket (dealer issue detection safety (DID-S))Keep the vehicle in the exclusion area |

| 4 | Burn mark | Check the vehicle for signs of burning, blistering and smoke in the area around the traction battery : 1.If there are burn marks1.1Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If there are no burn marks2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | -Recycling | An investigation is required by a PSA expert to understand the cause of the fault : Open an assistance ticket (dealer issue detection safety (DID-S))Acts of vandalism such as arson, or placing the vehicle next to a source of heat, should also be consideredKeep the vehicle in the exclusion area |

| 5 | Sign of impact on the lower part of the traction battery pack | With the vehicle on the ground, check the underside of the traction battery pack for signs of impact from underneath the vehicle (*)1.If the protective screens are damaged (or missing) and there are dents on the underside of the traction battery pack (*)1.1.Circle the result of step "NOK" according to the value observed2.If the protective screens are not damaged or only the fixings are damaged and there is no visible damage on the traction battery pack (*) 2.1.Circle the result of step "OK"2.2.Go to the next stepNote : (*) This point will be checked more closely in step 23 | OK / NOK | - Recycling - Overhaul | Refer to the method : "Check : Post-collision traction battery support" If the traction battery pack is deformed, contact the assistance team : Open an assistance ticket (dealer issue detection (DID))/!\ :No perforation is permitted => Recycling (Unsafe traction battery) |

| 6 | Sign of electrolyte leak | With the vehicle on the ground, check for signs of electrolyte leakage from underneath the vehicle(Electrolyte fluid is oilier than water and has a sweet-smelling odour that causes throat irritation when inhaled)1.If these signs are present1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If these signs are not present2.1Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling - Overhaul | An investigation is required by a PSA expert to understand the cause of the fault : Open an assistance ticket (dealer issue detection (DID))Place a retention container under the vehicle and keep the vehicle in the exclusion area => Overhaul (Only if the leak is limited to a small area) |

| 7 | Sign of coolant leak | With the vehicle on the ground, check for signs of coolant leakage with visible damage to the underside of the traction battery pack from underneath the vehicle (The protective screens are missing or severely damaged)1.If these signs are present1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If these signs are not present2.1.Circle the result of step "OK"3.If at this stage there are doubts about the source of the coolant3.1.Circle the result of step "Δ"3.2.This point will be checked more closely in step 223.3.Go to the next step | OK / Δ / NOK | - Recycling | Carry out the leak diagnostics procedure in accordance with the guided method "check of the drive train cooling circuit": Observation of significant internal leak: Whether a battery should be sent for recycling or not can be confirmed via subsequent checks for insulation faultsIf there is a leak in the external interface of the traction battery cooling circuit, before completely replacing the traction battery pack : => Replace the external pipe(s) of the cooling circuit(s) |

| |||||

| |||||

| 8 | Damage typical to a vehicle rollover | Check the vehicle for damage typical to a vehicle rollover (Damage to exterior mirror, wing and/or door with damage to the roof)1.If the vehicle has rolled over and there is visible damage to the traction battery pack1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If the vehicle does not have damage typical to a vehicle rollover2.1.Circle the result of step "OK"3.If the vehicle has rolled over but there is no visible damage to the traction battery pack3.1.Circle the result of step "Δ"3.2.This point will be checked more closely in step 223.3.Go to the next step | OK / Δ / NOK | -Recycling | If signs of impact were recorded in steps 5 and 23 and if the result of the diagnosis does not allow a conclusion to be drawn : Contact technical assistance => Keep the vehicle in the exclusion area |

| 9 | Signs of water exposure at a level higher than the door sill | Check if the vehicle has been submerged and/or exposed to a water level higher than the door sill for at least 30 minutes1.If the vehicle has been flooded1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If the vehicle has not been flooded2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling | If the vehicle has been flooded, the result "NOK" can be confirmed by taking a physical measurement of the insulation |

Checks using the diagnostic tool : - Checks to be carried out if the condition of the vehicle allows, vehicle in the exterior exclusion area and traction battery fitted to the vehicle - If this is not the case, return the vehicle to the workshop and immediately carry out steps 18 and onwards in the presence of a "flying doctor" in order to perform diagnostics on the removed traction battery

| Stage | Title | Description | Result | Destination | Action |

| 10 | Communication with the traction battery | Check communication with the traction battery ECU (BMU)1.If communication is not possible with the traction battery ECU (BMU) although it is possible with other ECUs : Problem with the traction battery ECU (BMU) or with the CAN connection to the vehicle or internal connection to the traction battery1.1.Circle the result of step "NOK"1.2.Contact a Flying doctor to establish, from step 20 onwards, a direct communication with the traction battery pack without passing via the vehicle’s diagnostic socket to validate or invalidate the status NOK of traction battery ECU (BMU)2.If communication is not possible with the traction battery ECU (BMU) or with any other ECUs2.1.Circle the result of step "Δ"2.2.Contact a Flying doctor to establish, from step 20 onwards, a direct communication with the traction battery pack without passing via the vehicle’s diagnostic socket to validate or invalidate the status NOK of traction battery ECU (BMU)3.If communication is possible with the traction battery ECU (BMU)3.1.Circle the result of step "OK"3.2.Go to the next step | OK / Δ / NOK | - Overhaul | - |

| - | Steps 11 to 17 relate to those faults that have a direct impact on the safe/unsafe classification of the traction battery : ⇒If the traction battery ECU (BMU) communicates, the fault codes reported must be compared to those in steps 11 to 17 ⇒If the traction battery ECU (BMU) does not communicate and some of the fault codes from steps 11 to 17 are present in the faults log, note down these codes in relation to the corresponding steps | ||||

| 11 | No voltage | Confirm that there is no voltage in the traction circuit1.If one or more fault codes P0AA1 67, P0AA1 73, P0AA4 67, P0AA4 73 are present1.1.The traction battery relays are bonded and voltage is still distributed throughout the vehicle1.2.Circle the result of step "Δ"2.If none of the previous fault codes are present2.1.Circle the result of step "OK"2.2.Go to the next step | OK / Δ | - | - |

| 12 | Vehicle involved in an accident and insulation problem | Check the presence of fault codes (P1AED 01) and (P0E74 01)1.If the fault codes 2 are present ⇒ /!\ Major risk1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If the fault codes 2 are not present simultaneously2.1.Circle the result of step "Δ"3.If none of the previous fault codes are present3.1.Circle the result of step "OK"3.2.Go to the next step | OK / Δ / NOK | - Recycling | Leave the vehicle in the exclusion area |

| 13 | Internal insulation faults | Check for internal insulation fault codes1.If fault code (P0E74 01) is present or fault codes (P2C86 12) and/or (P2C86 11) are present1.1.Perform steps 14 to 17 then refer to the guided method for insulation fault finding1.2.If the traction battery is affected : Circle the result of step "NOK"2.If no fault code is present2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling- Overhaul | - |

| 14 | External insulation faults | Check for external insulation faults1.If one of the 3 fault codes (P2C85 12), P2C85 11) or (P2C85 01) is present1.1.The problem is not necessarily caused by the traction battery pack1.6.Circle the result of step "Δ"2.If no fault code is present2.1.Circle the result of step "OK"2.2.Go to the next step | OK / Δ | - | This point will be checked more closely in step 20 |

| 15 | Temperature too high | Check the internal temperature of the traction battery :1.Measure and record :- The value of parameter ($D817) :Maximum temperature of the traction battery- The ambient temperature value1.1If the measured value is greater than 65°C or fault code (P058E 09) is present1.1.1.Circle the result of step "NOK"1.1.2.Quickly refer to the life situation "A"2.Wait for 4 hoursMeasure and record- The value of parameter ($D817) :Maximum temperature of the traction battery- The ambient temperature value2.1.If the value of the second measurement is higher than 65°C or it is higher than the first measurement at the same ambient temperature, or if fault code (P058E 09) is present2.1.1.Circle the result of step "NOK"2.1.2.Quickly refer to the life situation "A"3.If there are no fault codes, or the result of the second measurement is lower than the result of the first measurement and lower than 65°C3.1.Circle the result of step "OK"3.2.Go to the next stepComments : If measurement is not possible using the diagnostic tool - Every 4 hours, carry out physical measurements on the lower surface of the traction battery pack using an infrared thermometer - Note any changesResume contact with technical assistanceIf no means is available for measuring the temperature, contact a flying doctor | OK / NOK | - Recycling | Leave the vehicle in the exclusion area |

| 16 | Incorrect voltage on one of the traction battery cells | Check for fault codes (P0DE6 16) and (P0DE7 09), then measure the following parameters : - Voltage measured on the lowest cell of the traction battery ($D86F) - Voltage measured on the highest cell of the traction battery ($D870)1.First case : If fault code (P0DE07 09) is present and the value of voltage on the highest cell ($D870) is greater than 5 V1.1.Circle the result of step "NOK" => Unsafe traction battery1.2.Quickly refer to the life situation "A"2.Second case :If fault code (P0DE07 09) is present and the value of voltage on the highest cell ($D870) is around 4,35 V2.1.Circle the result of step "OK" => Safe traction battery2.2.Quickly refer to the life situation "B"3.Third case :2.If no fault codes are present or the parameter values are within the tolerance limit2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Overhaul | - |

| 17 | Main fuse out of service and incorrect voltage on the traction battery pack | Check the faults log for the presence of the following fault codes and confirm by measuring the voltage parameters- If fault code (P0A95 13) is present and the traction battery (D815) voltage value is less than one hundred volts (approximately 15 volts) and the value of the sum of all the traction battery (D438) cell voltages is equal to the traction battery (D815) voltage value (Plus or minus 10 V)1.1.If the finding is verified1.1.1.Circle the result of step "NOK"1.1.2.Quickly refer to the life situation "A"2.If the finding is not verified2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling-Repair- Overhaul | -If the external root cause on the traction battery pack is confirmed during fault finding :Check the conformity of cell voltage valuesIf the voltage values conform ⇒ (The traction battery is safe -If the internal root cause on the traction battery pack is confirmed during fault finding ⇒The traction battery is not safe |

Final checks :The vehicle can be returned to the workshop and placed on a lift in a secure area in order to immediately proceed with the next steps and carry out fault finding

| Stage | Title | Description | Result | Destination | Action |

| - | - | Isolate the vehicleIf it is not possible to isolate the vehicle as a result of the damage incurred, contact a flying doctor before proceeding to the next step | - | - | - |

| 18 | Lockout of the vehicle | Isolate the vehicleIf it is not possible to isolate the vehicle as a result of the damage incurred, contact a flying doctor before proceeding to the next step | - | - | - |

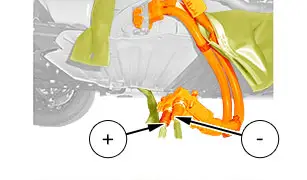

| 19 | Measurement to check for no voltage | Voltage is present at the traction battery pack terminals on one of the power connectors1.If there is voltage present1.1.Circle the result of step "Δ" provided that the power connectors are not damaged1.2.Go to the next step2.No voltage2.1.Circle the result of step "OK"2.2.Go to the next step | OK / Δ | -Repair- Overhaul | If there are no other subsequent faults in the checklist, the traction battery must be transported in standard packaging /!\ :Insulate the power connectorsRecord in writing the presence of voltage on the traction battery packPossible causes of voltage being present : - Relay stuck- Insulation fault upstream of the relays |

| 20 | Insulation check of the traction battery external circuit(Using the insulation tester: [CTRL-ISOL] / [EL-50774] | To be carried out only if there is no voltage at the terminals of the traction battery pack (in step 19) and if there is an insulation fault on the traction battery pack ⇒Measurement to be performed with relays open1.If there is an insulation fault between HV+ and earth and/or HV- and earth1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If insulation is correct2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | -Repair- Overhaul |

|

| Perform insulation checks on the base of the power connectors at the traction battery outlet :- Base of outlet to charging socket unit- Base of outlet to electric drive machine : Offset the measurement ; Using the electrical harness (part number 9832922980 ) | |||||

| |||||

| 21 | Insulation check of the traction battery internal circuit | In the event of an internal insulation fault (Step 13 NOK)Check for internal insulation fault codes on the traction battery1.If one of the 3 fault codes P0E74 01, P2C86 12 or P2C86 11 is present1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If no fault code is present2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling- Overhaul | Procedure :- Restore the 12 V network (Ancillaries battery)- Reconnect the CAN network socket on the traction battery if the measurement is performed via the vehicle’s diagnostic socket /!\ : The power network remains disconnected |

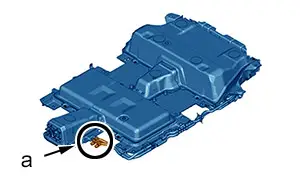

| 22 | Internal coolant leak in the traction battery pack | If there is a lack of coolant in the expansion tank and after eliminating the cause of a leakage from the electric drive machine or from the on-board charger/direct voltage transformer assembly (In accordance with guided method no. XXX) -Check that there is no internal coolant leakage from the traction battery pack : ⇒With the vehicle on a lift ⇒With all of the protective screens under the body removed-Purge the traction battery cooling circuit-Uncouple the cooling circuit at the inlet of the traction battery pack-Connect the tool to the Quick connect of the traction battery pack inlet-Plug the return by placing a cap on the Quick connect of the traction battery pack outlet (In "a")1.If a vacuum is not maintained and the coolant leak is not coming from the pipes or external connections, the leak is internal (cooling plates or interface)1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If the traction battery has no internal coolant leakage2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling | For the eCMP platform : |

| |||||

| For the eK0 platform, the cooling circuit pipes are located on top of the traction battery pack and this check can only be carried out after removing the traction battery (Stage 24) | |||||

| |||||

| 23 | Sign of impact on the lower part of the traction battery pack | Check that there is no sign of impact on the lower section of the traction battery pack in accordance with the assessment procedure for step 5 ⇒With the vehicle on a lift ⇒With all of the protective screens under the body removed | OK / NOK | - Recycling- Overhaul | Refer to the method : Check : Post-collision traction battery supportIf the traction battery pack is deformed, contact the assistance team/!\ :No perforation is permitted => Recycling (Unsafe traction battery) |

| 24 | Removing the traction battery pack ; Using a lifting table | Remove the traction battery pack from the vehicle | - | - | - |

| 25 | Pressure equalisation membranes | Check the pressure equalisation membranes1.If one of the 2 membranes is missing or loose (clipping, turning, etc.) or there is a visible sign of degassing1.1.Circle the result of step "NOK"1.2.Quickly refer to the life situation "A"2.If the traction battery has not been degassed2.1.Circle the result of step "OK"2.2.Go to the next step | OK / NOK | - Recycling | - |

| 26 | Other faults | There is a fault other than those previously mentionedExample: Traction battery (SOH) charge status insufficient | OK | -Repair- Overhaul | - |

Peugeot 308 2021-2026 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image