Peugeot 308: Dismantling : Engine bottom

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

1. Tooling

Workshop equipment : Piston ring pliers.

2. Preparation

Fix the engine to the stand.

Drain the engine oil.

Remove :

- The cylinder head

- The cylinder head gasket

- The coolant pump

- The oil pressure sensor

- The coolant inlet manifold

- The knock sensor

- The oil cooler

- The oil pump

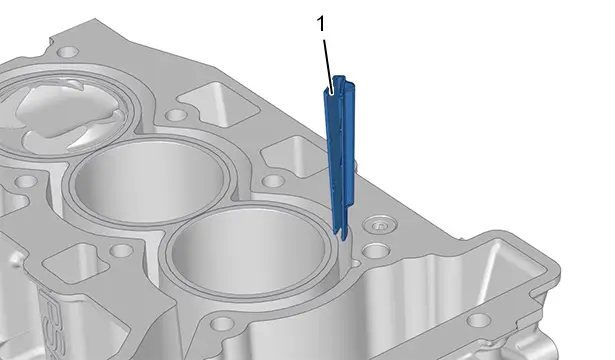

CAUTION : Risk of destroying the engine by overheating if the engine coolant deflector (1) is absent or incorrectly fitted.

Remove the deflector (1).

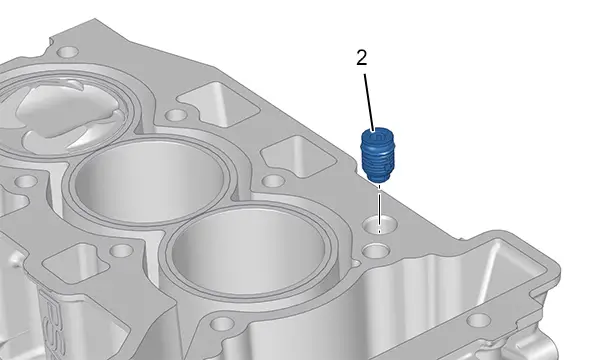

Remove the oil non-return valve (2).

3. Crankshaft

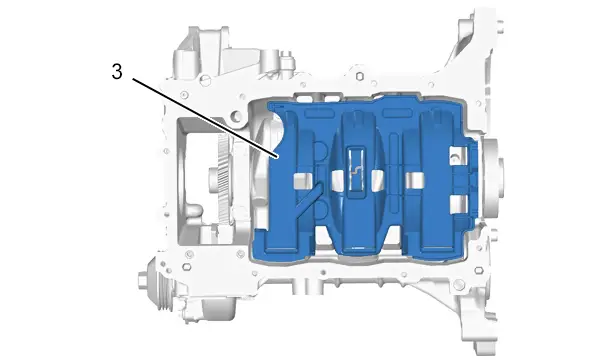

Remove :

- The anti-foaming baffle (3)

- The balancing shaft sprocket

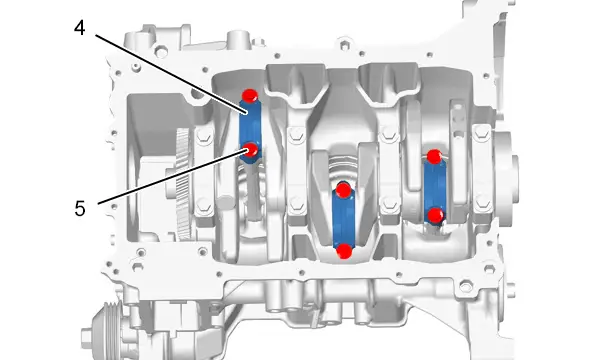

CAUTION : Mark the fitting orientation of the big end caps (4) before removal.

Remove :

- The bolts (5)

- The big end caps (4)

Turn the crankshaft slightly to detach the con rods.

CAUTION : Do not change the big end caps (4).

Refit :

- The big end caps (4)

- The bolts (5)

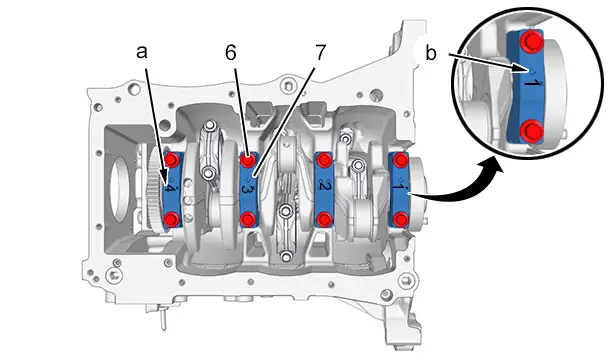

CAUTION : Mark the direction of fitting of the crankshaft main bearing caps (7) before removal.

The crankshaft main bearing caps (7) are numbered from 1 to 4(at "a") (Cylinder 1 is flywheel end ).

The concave part of each crankshaft bearing (7) (at "b") must be directed to the exhaust side.

Remove :

- The bolts (6)

- The main bearing caps (7)

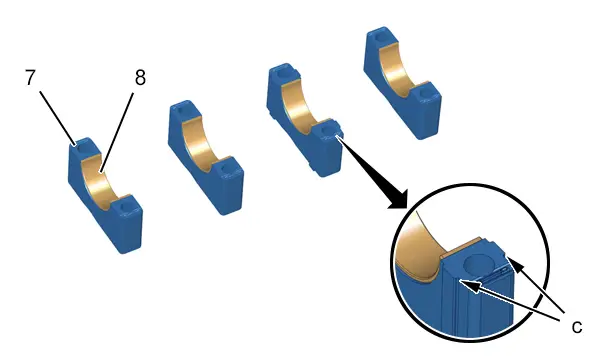

Remove the crankshaft smooth half-shells (8) from the crankshaft main bearing caps (7).

N.B. : Bearing number 2 is wider (at "c") to retain the crankshaft end float shims.

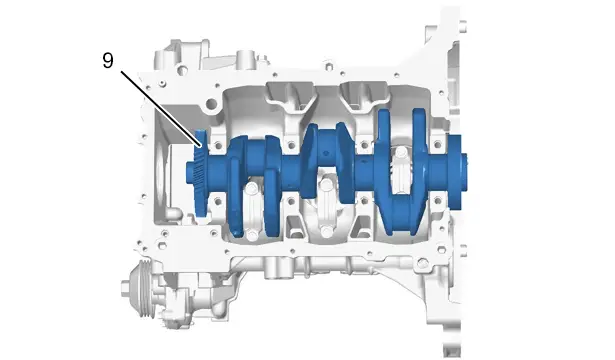

CAUTION : When removing the crankshaft, take care not to damage parts.

Remove the crankshaft (9) from the cylinder block .

4. Crankshaft bearing half-shells

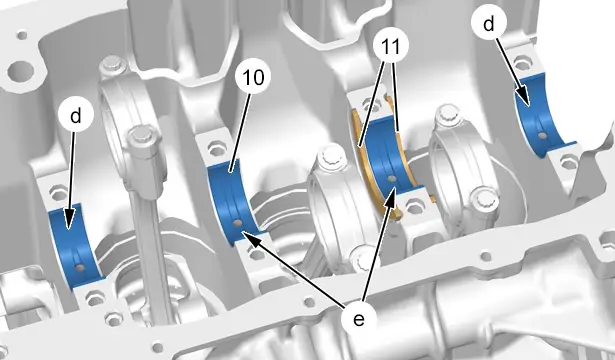

CAUTION : The crankshaft bearing half-shells (10) numbered 1 and 4 are partially grooved(at "d").

CAUTION : The crankshaft bearing half-shells (10) numbered 2 and 3 are fully grooved(at "e").

Remove :

- The two crankshaft lateral play flanges (11) on bearing n°2

- The grooved crankshaft bearing shells (10)

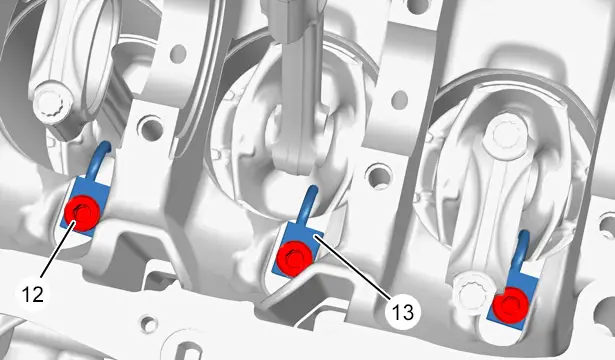

5. Piston bottom cooling oil nozzles(depending on equipment)

Remove :

- The bolts (12)(depending on equipment)

- The piston skirt spray jets (13)(depending on equipment)

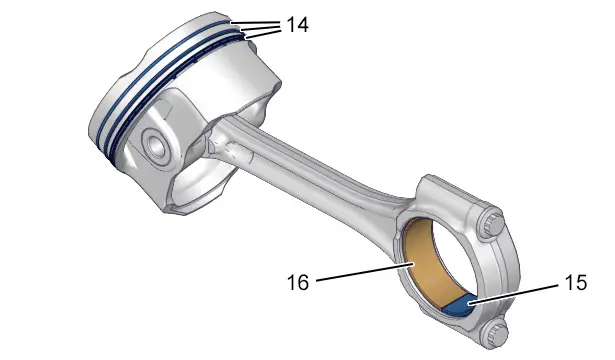

6. Connecting rod/piston assemblies

Remove the upper (16) and lower (15) half-shells.

CAUTION : Only the big end lower half-shells (15) are classed.

Remove the piston rings (14) ; Using piston ring pliers .

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image