Peugeot 308: Draining - filling - bleeding : Electric drive chain cooling circuit

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

CAUTION : Refer to the vehicle’s servicing schedule for the coolant checking interval.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Tooling

Workshop equipment :

- 2 bleed pipes

- Diagnostic tool

- Compressed air blower

- A coolant container holding approximately 13 litres of coolant

- A collar Rislan

- PH strips

| tool | Reference | Description |

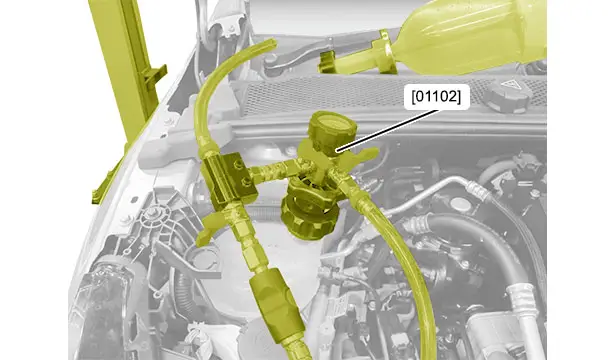

| [01102] | Tool for filling the cooling system by vacuum |

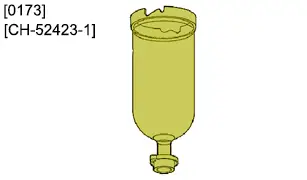

| [0173] | Bayonet filling cylinder |

| [CH-52423-1] | ||

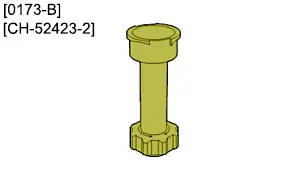

| [0173-B] | Adaptor / extension for bayonet filling cylinder |

| [CH-52423-2] | ||

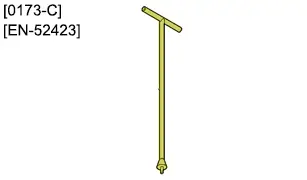

| [0173-C] | blocking rod for filling cylinder |

| [EN-52423] | ||

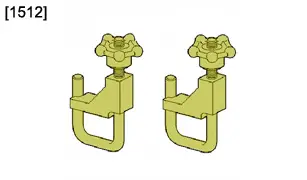

| [1512] (*) | Pipe clamp |

| (*) Use standard workshop equipment if the special too is not available | ||

2. Checking the coolant fluid

Check the pH of the coolant ; Using reactive strips.

N.B. : The pH value of the coolant should be between 6,3 and 8.

Replace the coolant if the pH value is out of tolerance.

3. Specific procedure when working on a component of the electric drive train cooling circuit

Components requiring a complete procedure

(Draining, filling and degassing

(Draining, filling and degassing

) :

) :

- Electric drive machine with reduction gear

- Traction battery

- Water condenser

Components requiring degassing only

(Use of pipe clamps without draining the electric drive train cooling circuit

(Use of pipe clamps without draining the electric drive train cooling circuit

) :

) :

- Electric drive train cooling circuit coolant pump

- Heating circuit electric coolant pump

- Traction battery cooling circuit coolant pump

- 3-way solenoid valve

- 2-way solenoid valve

- On-board charger/direct voltage transformer assembly

- Heater matrix

- Electric coolant heater

- Electric drive train cooling circuit radiator

- Coolant - air conditioning heat exchanger

4. Preliminary operations

Put the vehicle on a lift.

Remove :

- The expansion tank cap

- The under-engine protector

- The under-body traction battery protection

5. Draining the electric drive train cooling circuit

N.B. : Position a clean tray under the vehicle to collect the electric drive train cooling circuit coolant.

CAUTION : Use a container large enough to collect all of the electric drive train cooling circuit coolant.

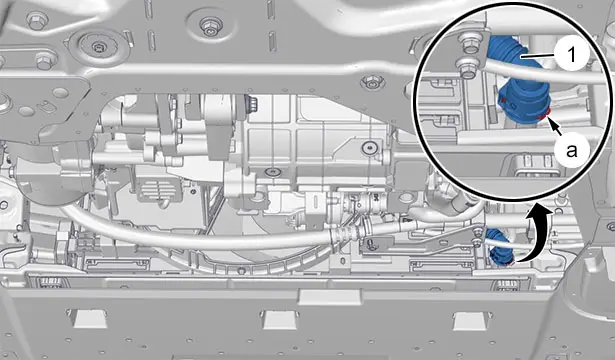

Uncouple the cooling pipe (1) (at "a").

Allow the coolant to run out.

Drain the electric drive train cooling circuit ; Using an air blower .

Couple the cooling pipe (1) (at "a").

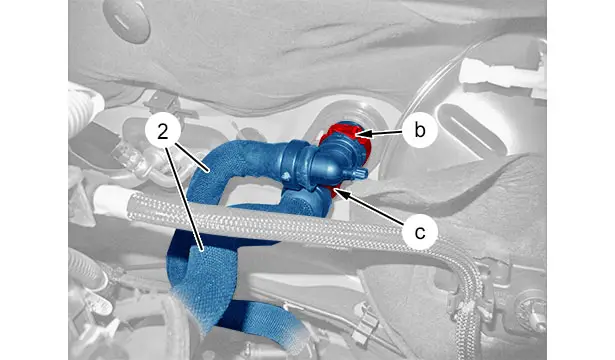

Uncouple the heater matrix cooling circuit pipes (2) (at "b", "c").

Allow the coolant to run out.

Drain the electric drive train cooling circuit ; Using an air blower .

N.B. : An additional quantity of fluid runs out.

Couple the cooling pipes (2).

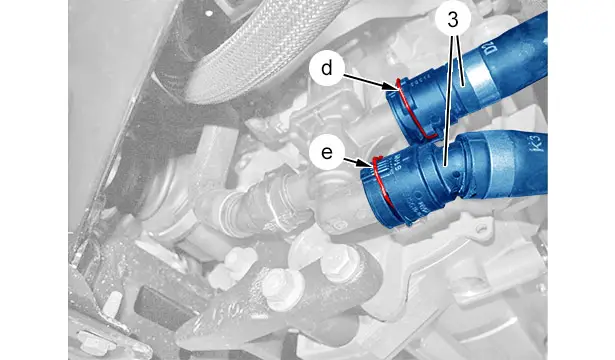

Uncouple the 3-way solenoid valve cooling pipes (3) (at "d", "e").

Allow the coolant to run out.

Drain the electric drive train cooling circuit ; Using an air blower .

Couple the cooling pipes (3).

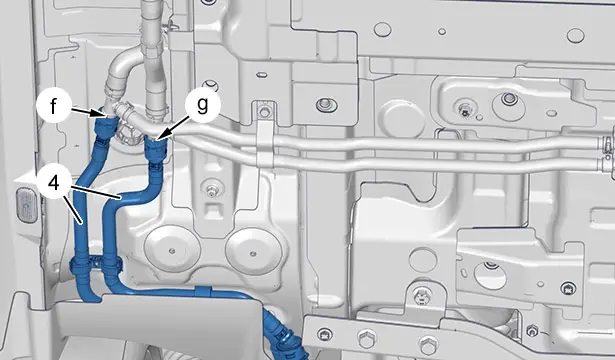

Uncouple the traction battery cooling circuit pipes (4) (at "f", "g").

Allow the coolant to run out.

Drain the electric drive train cooling circuit ; Using an air blower .

N.B. : An additional quantity of fluid runs out.

Couple the cooling pipes (4).

6. Filling the electric drive train cooling circuit

CAUTION : If the electric drive train cooling circuit is contaminated, rinse with clean water.

CAUTION : Always use new coolant.

CAUTION : Each filling operation must always be followed by an electric drive train cooling circuit degassing procedure.

Position the tool [01102] on the electric drive train cooling circuit expansion tank .

Prepare a coolant container holding 13 litres of coolant.

N.B. : The receptacle must be positioned slightly lower than the equipment for filling by vacuum.

To perform electric drive train cooling circuit vacuum extraction ; Using the diagnostic tool :

- Connect the diagnostic tool

- Access the sub-menu : Electric drive train supervisor ECU / Service action / Vacuum draining

- Activate the electric drive train cooling circuit vacuum extraction procedure

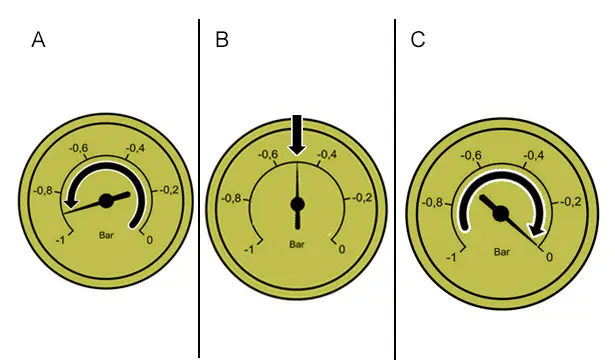

Place the electric drive train cooling circuit under a vacuum to reach -0,9 bar (diagram "A").

Wait 10 seconds and check that the value obtained does not drop.

ESSENTIAL : Start the filling procedure, using the diagnostic tool when the pressure in the circuit exceeds -0,5 bar during filling.

Start the diagnostic tool.

Access the sub-menu : Electric drive train supervisor ECU / Service action / Filling the cooling system.

Open the coolant inlet valve on the tool [01102] to start filling.

If the pressure read is -0,5 bars : Activate the electric drive train cooling circuit vacuum extraction procedure (diagram "B").

Fill the electric drive train cooling circuit completely and wait for the pressure to return to 0 bar (diagram "C").

N.B. : There must be a high level of coolant in the expansion tank. If the coolant level is below the halfway line of the expansion tank, repeat the vacuum extraction.

CAUTION : Remove the tool [01102] and rinse the assembly with clean water.

Fill the expansion tank with coolant until level with the cap.

7. Degassing and checking of the electric drive train cooling circuit

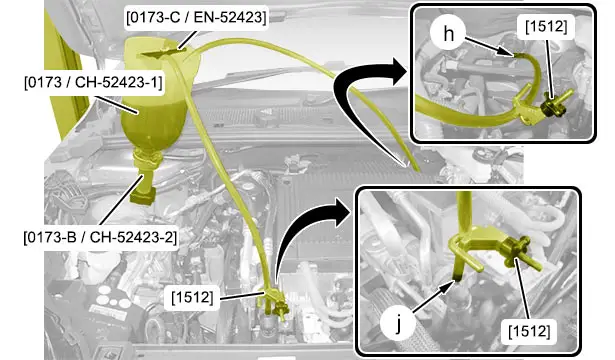

Position the tool [0173 / CH-52423-1], [0173-B / CH-52423-2], [0173-C / EN-52423] on the filler neck.

Close the closer [0173-C / EN-52423] on the filling cylinder [0173 / CH-52423-1].

Position the tool [1512] on the bleed pipes and close them.

Couple the bleed pipes to the heater matrix outlet drains (at "h") and to the coolant - air conditioning heat exchanger inlet (at "j").

Hold the bleed pipes in place in the filling cylinder [0173 / CH-52423-1] ; Using a collar Rislan.

Pour 1 litre of coolant into the filling cylinder and open it.

Remove the tools [1512].

CAUTION : Check that the level of coolant in the filling cylinder is sufficient during the degassing procedure ; Never fill above the halfway point of the filling cylinder to avoid spills when handling the solenoid valves and pumps.

To degas the engine cooling system ; Using the diagnostic tool :

- Access the sub-menu : Electric drive train supervisor ECU / Repair / Venting of the cooling circuit

- Follow the instructions on the diagnostic tool

At the end of the degassing procedure :

- Disconnect the diagnostic tool

- Blank the filling cylinder [0173 / CH-52423-1] using the blocking rod [0173-C / EN-52423]

Remove :

- The bleed pipes and close the heater matrix outlet bleed screws (at "h") and the coolant - air conditioning exchanger inlet (at "j")

- The filling cylinder [0173 / CH-52423-1], [0173-B / CH-52423-2]

N.B. : The level in the expansion tank must be 5 mm above the maximum.

Top up the coolant in the expansion tank.

8. Additional operations

Refit :

- The expansion tank cap

- The under-body traction battery protection

- The under-engine protector

- The vehicle to its wheels

Switch on the electric drive machine.

N.B. : The coolant level must be checked when cold ; Never open the expansion tank plug when the fluid is hot.

Check the coolant level and top up, if required.

CAUTION : Check that there are no coolant leaks.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image