Peugeot 308: Draining - filling - bleeding : Hybrid drive train cooling circuit

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

CAUTION : Refer to the vehicle’s servicing schedule for the coolant checking interval.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Tooling

Workshop equipment : Bleed pipe.

| tool | Reference | Description |

| [01102] | Tool for filling the cooling system by vacuum |

| [0173][EN-52423] | Filling cylinder for bleeding cooling circuits |

2. Checking the coolant fluid

Check the pH of the coolant ; Using reactive strips.

N.B. : The pH value of the coolant should be between 6,3 and 8.

Replace the coolant if the pH value is out of tolerance.

3. Preliminary operations

Place the vehicle on a 2-post lift.

Remove :

- The expansion tank cap

- The under-engine protector

- The front left-hand under-body protector

4. Draining the hybrid drive train cooling circuit

ESSENTIAL : The traction battery charge level must be at least 20% of the total charge capacity before initiating the draining/filling/bleeding procedure on the hybrid drive train cooling circuit : At least 1 line on the traction battery charge level gauge is required.

N.B. : Place a clean tray underneath the engine to collect the coolant from the hybrid drive train cooling circuit.

CAUTION : Use a container large enough to collect all of the hybrid drive train cooling circuit coolant.

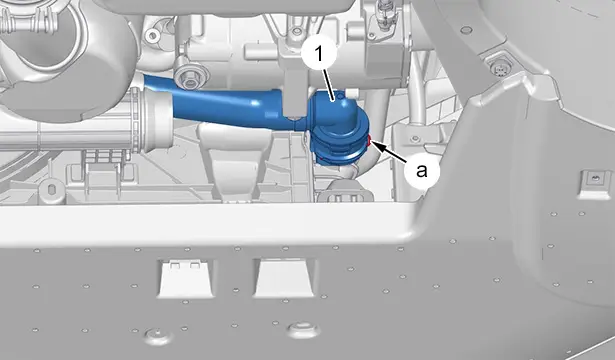

Unclip (at "a").

Uncouple the engine cooling radiator cooling pipe (1).

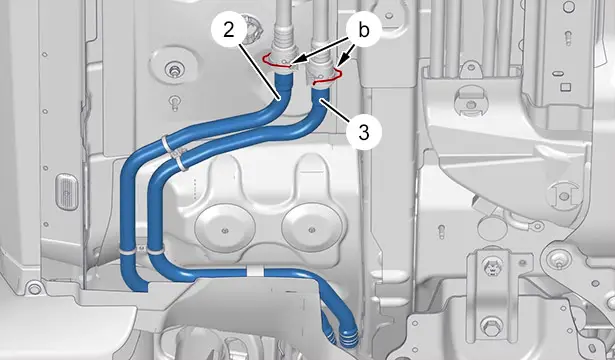

Unclip (at "b").

Detach and move aside :

- The hybrid drive train cooling circuit pipe (2)

- The hybrid drive train cooling circuit pipe (3)

Allow the hybrid drive train cooling circuit coolant to drain.

Couple the engine cooling radiator cooling pipe (1).

Reclip (at "a").

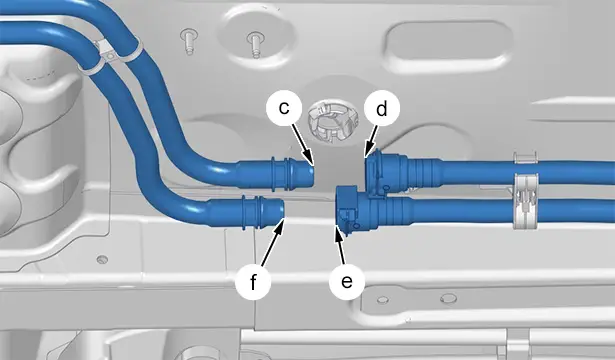

Drain the hybrid drive train cooling circuit (Engine cooling radiator side) (At "c" or "f") ; Using an air blower .

Drain the hybrid drive train cooling circuit (Side : On-board charger/direct voltage transformer assembly) (At "d" or "e") ; Using an air blower .

N.B. : An additional quantity of fluid runs out.

Allow the hybrid drive train cooling circuit coolant to drain.

CAUTION : If the tool for filling the cooling system by vacuum [01102] is used, measure the quantity of coolant drained.

5. Filling the hybrid drive train cooling circuit

CAUTION : If the hybrid drive train cooling circuit is contaminated, rinse with clean water.

CAUTION : Always use new coolant.

CAUTION : Each filling operation must always be followed by a hybrid drive train cooling circuit degas operation.

Couple up :

- The hybrid drive train cooling circuit pipe (2)

- The hybrid drive train cooling circuit pipe (3)

Reclip (at "b").

Position the cooling circuit vacuum filling tool [01102] on the hybrid drive train cooling circuit expansion chamber .

CAUTION : To avoid entry of air into the circuit, allow for 20% of additional coolant.

Prepare a receptacle of coolant containing the quantity of fluid drained + 20 %.

N.B. : The receptacle must be positioned slightly lower than the equipment for filling by vacuum.

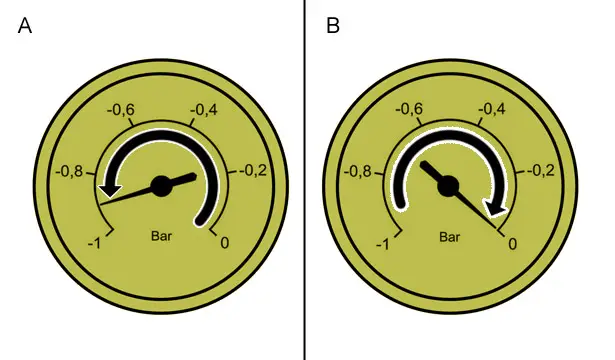

Place the hybrid drive train cooling circuit under a vacuum to reach -0,9 bar (diagram "A").

Wait 10 seconds and check that the value obtained does not drop.

Fill the hybrid drive train cooling circuit completely and wait for the pressure to return to 0 bar (diagram "B").

CAUTION : Remove the equipment for filling by vacuum [01102] and rinse the assembly with clean water.

6. Degassing and check of the hybrid drive train cooling circuit

ESSENTIAL : The air conditioning control should not operate during this phase.

CAUTION : In the event that the internal combustion engine or the hybrid drive train cooling circuit electric coolant pumps stop during the degassing procedure, repeat all the operations in the hybrid drive train cooling circuit degassing procedure.

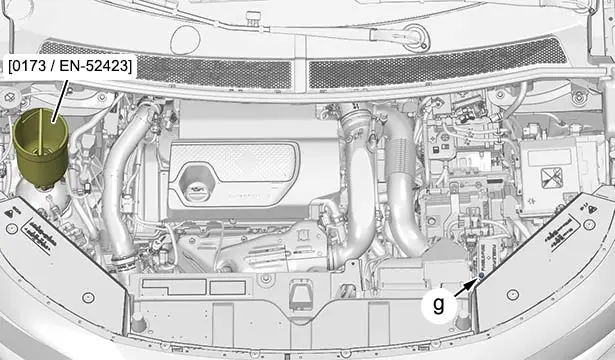

Position the tool [0173 / EN-52423] on the filler neck.

Open the cap on the filling cylinder [0173 / EN-52423].

Remove the bleed plug (at "g").

Fit a bleed pipe between the filling cylinder [0173 / EN-52423] and the bleed union (at "g").

Procedure for activating the degassing procedure :

- Start the engine

- Accelerate to an engine speed above 1600 rpm (for 10 seconds) to activate the hybrid drive train cooling circuit degas mode

ESSENTIAL : Activating the fan assembly for a few seconds validates the change to aftersales mode, otherwise the hybrid drive train cooling circuit degassing procedure should be repeated.

CAUTION : Check that the level of coolant in the filling cylinder is sufficient.

Maintain the engine speed between 2000 and 2500 rpm : During the degassing procedure.

N.B. : Once the degassing procedure is activated, the coolant temperature regulation threshold changes to 80°C, followed by the automatic activation of the hybrid drive train cooling circuit electric coolant pumps continuously.

N.B. : The temperature of the coolant continues to rise until it reaches 97°C, then the fan assembly engages in order to lower the temperature to 94°C.

N.B. : The degassing procedure ends after 2 triggering cycles and once the fan assembly has stopped.

N.B. : Do not remove the filling cylinder while the engine is hot.

Switch off the ignition.

Leave the engine to cool.

Remove the bleed pipe (at "g").

Refit the bleed plug (at "g").

Blank the filling cylinder [0173 / EN-52423] using the blocking rod .

Remove the filling cylinder [0173 / EN-52423].

CAUTION : Do not fill the system past the max mark.

Check the coolant fluid level.

7. Additional operations

Refit :

- The expansion tank cap

- The front left-hand under-body protector

- The under-engine protector

- The vehicle to its wheels

CAUTION : Check that there are no coolant leaks.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image