Peugeot 308: Refitting : Engine top

ESSENTIAL : Follow the safety instructions

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

CAUTION : This procedure is intended for the replacement of faulty internal components of the cylinder head. If the cylinder head is damaged, replace it with a new cylinder head.

1. Replacement of parts in all cases

| Description | Quantity |

| Valve stem seals | 12 |

| Cylinder head gasket | 1 |

| Cylinder head bolt | 11 |

2. Tooling

N.B. : Use the products recommended by the manufacturer

.

.

Workshop equipment :

- Valve spring compressor (Type U.43 LA)

- Cylinder head support (Type U.43)

| Tool | Reference | Description |

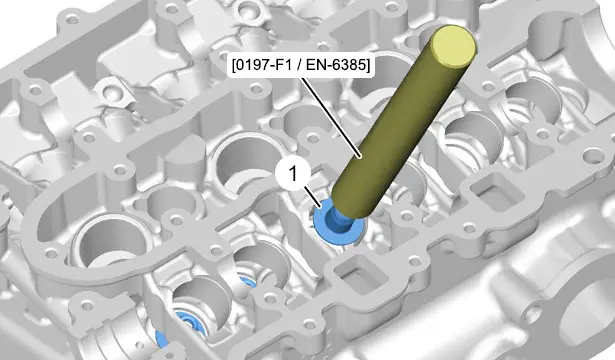

| [0197-F1][EN-6385] | Tool for refitting valve stem seals |

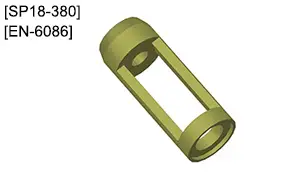

| [SP18-380][EN-6086] | Spring compressor |

3. Preliminary operation

Check the flatness of the cylinder head

.

.

4. Refitting of valves

4.1. Refitting of valve stem seals

The valve stem seals (1) must be put in place by hand and fully in their housing.

Refit the valve stem seals (1) (new) ; Using the tool [0197-F1 / EN-6385].

Oil and refit the valves ; With engine oil .

4.2. Refitting of valve springs

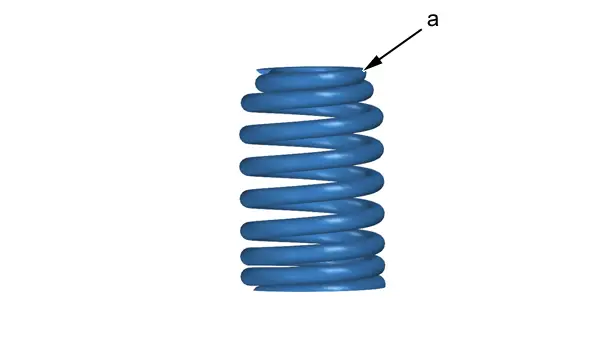

N.B. : Direction of fitting of the valve springs small diameter at the top (at "a").

Refit the valve springs .

4.3. Refitting of valves

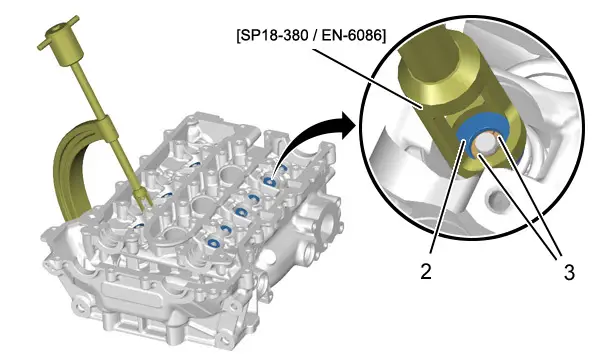

Refit the upper cup (2).

Fit the valve spring compressor tool on the cup (2) ; Using the tool [SP18-380 / EN-6086].

Compress the valve springs.

Refit the valve half-cones (3).

Remove :

- Valve spring compressor

- The tool [SP18-380 / EN-6086]

4.4. Refitting the hydraulic tappets

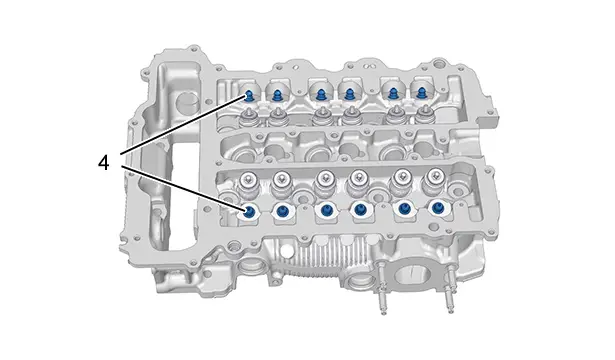

CAUTION : Oil the body of the hydraulic tappets (4) ; With engine oil.

Refit the hydraulic cam followers (4).

5. Refit the cylinder head

CAUTION : Observe the tightening torques

.

.

Refit the cylinder head

.

.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image