Peugeot 308: Check : Braking system

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

ESSENTIAL : All personnel working on vehicles with a fuel cell stack must have completed the STELLANTIS training courses required to work on these vehicles (observe the regulations in force in the respective country).

1. Foreword

This document describes a brake wear checking method, it can be printed, as can the associated methods, at the request of the customer.

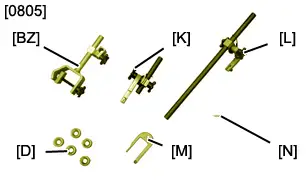

2. Tooling

N.B. : The kit [0805] is not available from replacement parts. As a replacement, a dial gauge magnetic support can be used which will guarantee the measurements.

Workshop equipment :

- Dial with needle

- Dial gauge

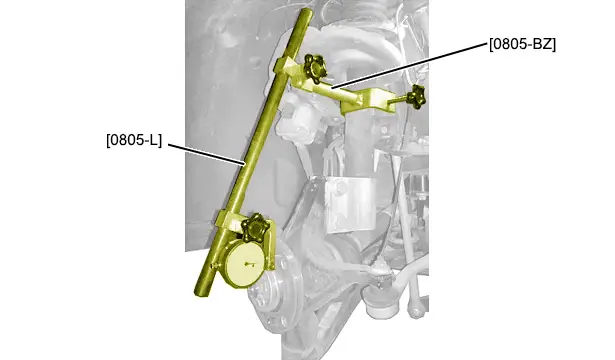

| Tool | Reference | Description |

| [0805] (*) | Disc/hub run-out checking tool |

| [0805-BZ] (*) | caliper | |

| [0805-K] (*) | Assembly : Disc check bracket / Ventilated disc fork | |

| [0805-L] (*) | Disc check bracket | |

| [0805-M] (*) | Non-ventilated disc fork | |

| [0805-D] (*) | Spacers | |

| [0805-N] (*) | dial gauge extension | |

| [0821] (*) | Set of feeler gauges to measure the brake pad wear |

| (*) Use standard workshop equipment if the special tool is not available | ||

3. Front brake disc

INTERNAL COMBUSTION DRIVE TRAIN OR PHEV DRIVE TRAIN OR ELECTRIC DRIVE TRAIN OR MHEV DRIVE TRAIN

CAUTION : Observe the tightening torques

.

.

Raise and support the vehicle on a 2 -post lift.

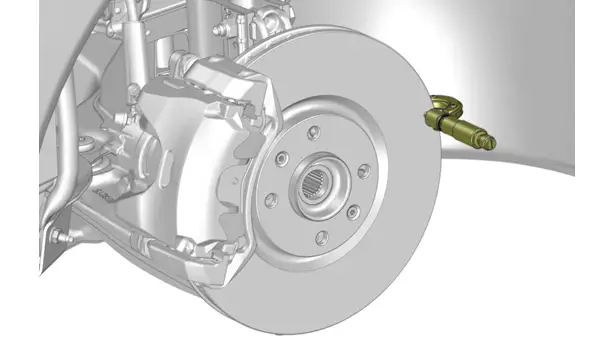

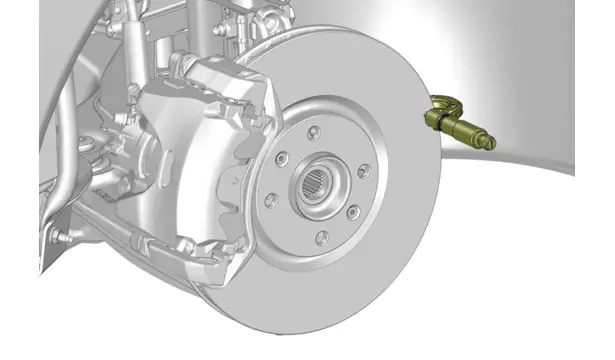

3.1. Checking the run-out of the front brake disc (Wheel fitted) (First possibility)

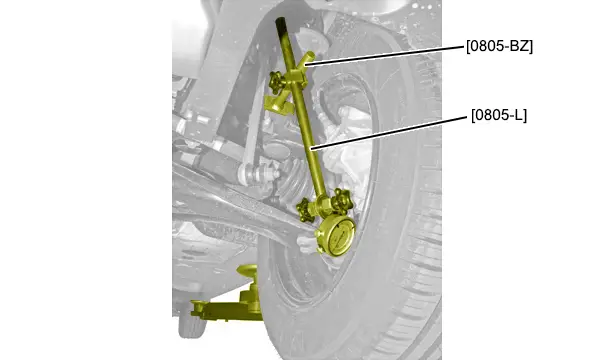

Fix :

- The assembly [0805-BZ], [0805-L] on the damper

- The dial gauge on the tool [0805-L]

Secure the tip of the dial gauge 10 mm from the edge of the front brake disc (the tip operated by the spring).

CAUTION : To check the front brake disc run-out, turn the disc by means of the driveshaft.

Carry out :

- A dial gauge zero reset

- One complete revolution of the front brake disc

Permissible run-out of the front brake disc assembled on the hub : Less than 0,05 mm.

3.2. Checking the run-out of the front brake disc (Wheel fitted) (Second possibility)

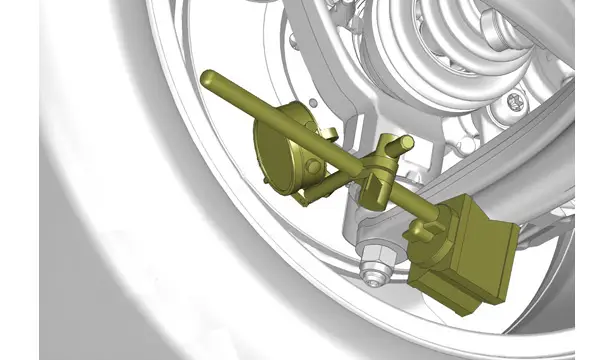

Fix :

- The assembly [0805-BZ], [0805-L] on the damper

- The dial gauge on the tool [0805-L]

Secure the tip of the dial gauge 10 mm from the edge of the front brake disc (the tip operated by the spring).

CAUTION : To check the front brake disc run-out, turn the disc by means of the driveshaft.

Carry out :

- A dial gauge zero reset

- One complete revolution of the front brake disc

Permissible run-out of the front brake disc assembled on the hub : Less than 0,05 mm.

3.3. Checking the run-out of the front brake disc (Wheel removed)

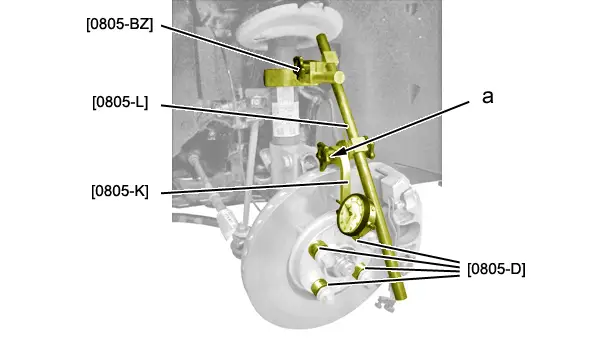

Refit and tighten the wheel bolts fitted with the tool [0805-D].

Check the runout of the brake discs ; Refer to chapters 3.1 and 3.2.

Permissible run-out of the front brake disc assembled on the hub : Less than 0,05 mm.

3.4. Checking the variation in the thickness of the front brake disc (Wheel removed) (First possibility)

Refit and tighten the wheel bolts fitted with the tool [0805-D].

Fix :

- The assembly [0805-BZ], [0805-L] on the damper

- The dial gauge on the tool [0805-K]

Loosen the tool [0805-K] (In "a").

Secure the tip of the dial gauge 5 mm from the edge of the front brake disc (the tip operated by the spring).

CAUTION : To check the variation in the thickness of the front brake disc, turn the brake disc by means of the driveshaft.

Carry out :

- A dial gauge zero reset

- One complete revolution of the front brake disc

Permissible variation in the thickness of the front brake disc over the same circumference of 0,01 mm.

3.5. Checking the variation in the thickness of the front brake disc (Wheel removed) (Second possibility)

Check the variation in the thickness over the circumference at 8 points 5 mm from the periphery of the front brake disc ; Using a micrometer (Capacity: 0 - 50 mm).

Permissible variation in the thickness of the front brake disc over the same circumference of 0,01 mm.

3.6. Checking the thickness of the front brake disc (Wheel removed)

Measure the thickness of the front brake discs on the friction surfaces ; Using a micrometer (Capacity: 0 - 50 mm).

See the table below.

Front discs

| Special feature | Nominal diameter of a new disc | Thickness of a new disc | Min. permissible thickness |

| Solid disc | 247 mm | 10 mm | 8 mm |

| 247 mm | 13 mm | 11 mm | |

| 266 mm | 13 mm | 11 mm | |

| Ventilated disc | 247 mm | 20,4 mm | 18,4 mm |

| 257 mm | 20,4 mm | 18,4 mm | |

| 257 mm | 22 mm | 20 mm | |

| Ventilated disc (ION / C-ZERO) | 257 mm | 17 mm | 15,4 mm |

| Ventilated disc | 266 mm | 20,4 mm | 18,4 mm |

| 266 mm | 22 mm | 20 mm | |

| 280 mm | 24 mm | 22 mm | |

| 280 mm | 28 mm | 26 mm | |

| 281 mm | 26 mm | 24 mm | |

| 283 mm | 26 mm | 24 mm | |

| 284 mm | 22 mm | 20,2 mm | |

| 285 mm | 28 mm | 26 mm | |

| 288 mm | 28 mm | 26 mm | |

| 294 mm | 24 mm | 22,4 mm | |

| 294 mm | 26 mm | 24,4 mm | |

| 300 mm | 24 mm | 22 mm | |

| 300 mm | 32 mm | 30 mm | |

| 302 mm | 26 mm | 24 mm | |

| 304 mm | 28 mm | 26 mm | |

| 309 mm | 32 mm | 30 mm | |

| 310 mm | 32 mm | 30 mm | |

| 330 mm | 28 mm | 26 mm | |

| 330 mm | 30 mm | 28 mm | |

| 340 mm | 30 mm | 28 mm | |

| 380 mm | 32 mm | 30 mm | |

| 323 mm | 28 mm | 26 mm |

4. Front hub

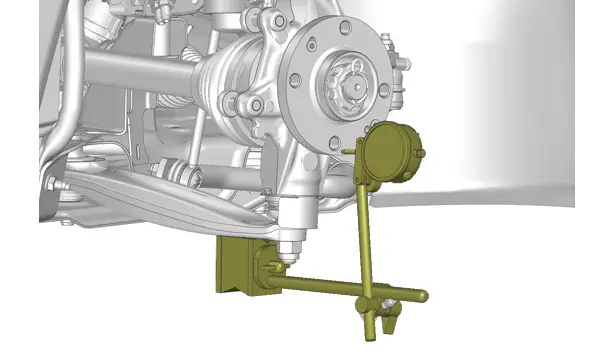

4.1. Checking the run-out : First possibility

Check the tightening torque of the driveshaft nut.

Clean the hub/front brake disc contact surface ; Using an abrasive cloth.

Fix :

- The assembly [0805-BZ], [0805-L] on the damper

- The dial gauge on the tool [0805-L]

Place the tip of the dial gauge in contact as close as possible to the outer edge of the front hub (the tip under the action of the spring).

CAUTION : To check the run-out of the front hub, turn the hub by means of the driveshaft.

Carry out :

- A dial gauge zero reset

- A complete revolution of the front hub

Permissible run-out of the front hub : Less than 0,013 mm.

4.2. Checking the run-out : Second possibility

Fix :

- The dial gauge magnetic support on the suspension lower arm

- The dial gauge on the magnetic support

Place the tip of the dial gauge in contact as close as possible to the outer edge of the front hub (the tip under the action of the spring).

CAUTION : To check the run-out of the front hub, turn the hub by means of the driveshaft.

Carry out :

- A dial gauge zero reset

- A complete revolution of the front hub

Permissible run-out of the front hub : Less than 0,013 mm.

5. Checking the thickness of the rear brake disc (wheel removed)

Release the handbrake..

Measure the thickness of the rear brake discs on the friction surfaces ; Using a micrometer (Capacity: 0 - 50 mm).

See the table below.

Rear discs

| Special feature | Nominal diameter of a new disc | Thickness of a new disc | Min. permissible thickness |

| Solid disc | 247 mm | 8 mm | 6 mm |

| Solid disc hub | 249 mm | 9 mm | 7 mm |

| 268 mm | 12 mm | 10 mm | |

| Solid disc | 272 mm | 12 mm | 10 mm |

| 274 mm | 14 mm | 12 mm | |

| 280 mm | 16 mm | 14 mm | |

| 290 mm | 10 mm | 8 mm | |

| 290 mm | 12 mm | 10 mm | |

| 290 mm | 14 mm | 12 mm | |

| 300 mm | 16 mm | 14 mm | |

| 302 mm | 10 mm | 8,4 mm | |

| Ventilated disc | 294 mm | 22 mm | 20 mm |

| 302 mm | 22 mm | 20 mm | |

| 323 mm | 28 mm | 26 mm |

6. Rear brake drum check

Release the handbrake..

Remove :

- The rear wheel

- The rear brake drum

Measure the internal diameter of the rear brake drums on the friction surface ; Using a vernier caliper .

See the table below.

Rear brake drum

| Drum (in inches) | Nominal diameter of a new drum | Maximum permitted diameter |

| 7 | 180 mm | 182 mm |

| 8 | 203 mm | 204,4 mm |

| 8 (ION / C-ZERO) | 203 mm | 205 mm |

| 9 | 228,6 mm | 229,8 mm |

| 10 | 254,15 mm | 256 mm |

Refit :

- The rear brake drum

- The rear wheel

7. Check of the thickness of the brake pad linings and brake shoe linings

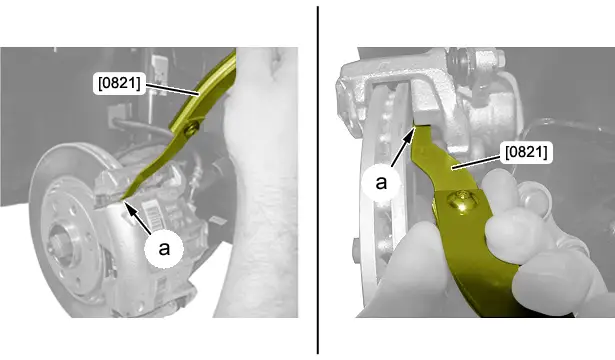

Check the rear brake pad wear ; Using the tool [0821].

N.B. : Take several measurements at the points accessible using the tool [0821](inside and outside) : For example at "a".

INTERNAL COMBUSTION DRIVE TRAIN OR PHEV DRIVE TRAIN OR ELECTRIC DRIVE TRAIN OR MHEV DRIVE TRAIN

| Vehicle | Minimum thickness of the brake pad linings (front) | Minimum thickness of the brake pad linings (rear) | Minimum thickness of the brake shoe linings |

| IOn (S3) | 2 mm | - | 1 mm |

| 107 (B0) | 1 mm | - | 1 mm |

| 108 (B3) | |||

| 206 (T1) | 2 mm | 2 mm | 1 mm |

| 206+ (T3E) | 2 mm | - | 1 mm |

| 207 (A7) | 2 mm | 2 mm | 1 mm |

| 207i Iran (T3I) | |||

| 207 Malaysia (T33) | |||

| 207 China (T3) | |||

| 207 Mercosur (T3) | |||

| 208 (A90) | 2 mm | 2 mm | 1 mm |

| 208 (A91) | |||

| 208 Mercosur (Al91) | 2 mm | 2 mm | 2 mm |

| 208 (P21) | 2 mm | 2 mm | 1 mm |

| 208 (P21) MHEV | 2 mm | 2 mm | 1 mm |

| e-208 (eP21) | 2 mm | 2 mm | 1 mm |

| 301 (M33) | 2 mm | - | 1 mm |

| 301 China (M33C) | 2 mm | 2 mm | - |

| 307 (T5) | 2 mm | 2 mm | - |

| 307 restyled (T6) | |||

| 308 (T7) | 2 mm | 2 mm | - |

| 308 (T9) | |||

| 308 China (TX3) | |||

| 308 Mercosur (T71) | |||

| 308 (P51) | 2 mm | 2 mm | - |

| 308 (P51) (PHEV / MHEV) | |||

| 308 (eP51) | |||

| RCZ (T75) | 2 mm | 2 mm | - |

| 407 (D2) | 2 mm | 2 mm | - |

| 408 Mercosur (T73) | 2 mm | 2 mm | - |

| 408 China (T73) | |||

| 408 Malaysia (T73MY) | |||

| 408 Russia (T7R) | |||

| 408 (P54) | 2 mm | 2 mm | - |

| 408 X (P54C) | 2 mm | 2 mm | - |

| 508 (W23) | 2 mm | 2 mm | - |

| 508 China (W23) | |||

| 508 (R8) | 2 mm | 2 mm | - |

| 508 L China (R83) | 2 mm | 2 mm | - |

| 607 (Z8) | 2 mm | 2 mm | - |

| 607 (Z9) | |||

| 807 (VV) | 2 mm | 2 mm | - |

| 1007 (A0) | 2 mm | 2 mm | 1 mm |

| 2008 (A94) | 2 mm | 2 mm | - |

| 2008 Mercosur (Al94) | |||

| 2008 (P24E) | |||

| 3008 (T84) | 2 mm | 2 mm | - |

| 3008 China (T88) | |||

| 3008 (P84) | |||

| 3008 (P64) | |||

| 4007 (I3) | 2 mm | 2 mm | 1 mm |

| 4008 (J3) | 2 mm | 2 mm | 1 mm |

| 4008 China (P84C) | 2 mm | 2 mm | - |

| 5008 (T87) | 2 mm | 2 mm | - |

| 5008 (P87) | |||

| 5008 China (P87C) | |||

| 5008 (P74) | |||

| Rifter (K9) | 2 mm | 2 mm | - |

| TRAVELLER (K0) | 2 mm | 2 mm | - |

| BIPPER (A9) | 2 mm | - | 1 mm |

| PARTNER I (M49) | 2 mm | - | 1 mm |

| PARTNER II (M59) | 2 mm | 2 mm | 1 mm |

| PARTNER III (B9) | |||

| PARTNER IV (K9) | 2 mm | 2 mm | - |

| EXPERT I (U65) | 2 mm | - | 1 mm |

| EXPERT II (U65) | |||

| EXPERT III (G9) | 2 mm | 2 mm | 1 mm |

| EXPERT IV (K0) | 2 mm | 2 mm | - |

| BOXER II (U5) | 2 mm | 2 mm | 1 mm |

| BOXER III (U9) | |||

| BOXER (X250 MCA) | 2 mm | 2 mm | 1 mm |

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image