Peugeot 308: Maintenance : Technical assessment of the braking

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

ESSENTIAL : All personnel working on vehicles with a fuel cell stack must have completed the STELLANTIS training courses required to work on these vehicles (observe the regulations in force in the respective country).

1. Tools

Tools and equipment required to carry out the check.

A micrometer.

| tools | Reference | Description |

| [0821] | Set of feeler gauges to measure the brake pad wear |

| [CH-52291] |

2. Method of checking

Fill in the form manually as the checks are carried out.

Place the vehicle on a 2-post lift.

2.1. In the passenger compartment

Switch on the ignition.

Make the following checks :

- The brake fluid level warning lamp should switch off after a brief instant

- Parking brake lever : Length of the travel, fixing, switching on of the warning lamp (Refer to the corresponding parking brake adjustment method)

- Check that the brake lamps come on

2.2. Under hood

CAUTION : Brake fluid is toxic. Avoid all contact with skin and eyes. In the event of contact with the eyes, rinse them immediately with copious amounts of water for several minutes.

CAUTION : Brake fluid is highly corrosive to paintwork. If any is projected onto the bodywork, clean the surface immediately.

ESSENTIAL : Any contamination of the brake fluid is forbidden. The brake fluid should be clear and free from sediments or floating substances.

ESSENTIAL : Use only approved and recommended hydraulic fluids.

Visually check :

- No leaks and the appearance of the reservoirs and pipes of the braking circuit

- The condition of the brake vacuum pipes

- The brake fluid level in the reservoir

N.B. : Brake fluids of homologation standards DOT3, DOT4 and DOT5.1 are compatible.

CAUTION : Brake fluid of homologation standard DOT5 is not compatible with DOT3, DOT4, DOT5.1.

2.3. Raise and chock the vehicle at mid-height

Check that the wheels rotate freely (Brake seized).

Remove the wheels.

Visually check :

- That there are no leaks on the brake calipers and brake hoses

- The condition of the brake calipers and dust guards

- The condition of the brake discs : No distortion, scratches

- The condition of the brake pad warning lamp wires (According to equipment)

- The condition of the brake drums and wheel cylinders : No leaks (According to equipment)

Check the wear of the brake discs

(Using a micrometer).

(Using a micrometer).

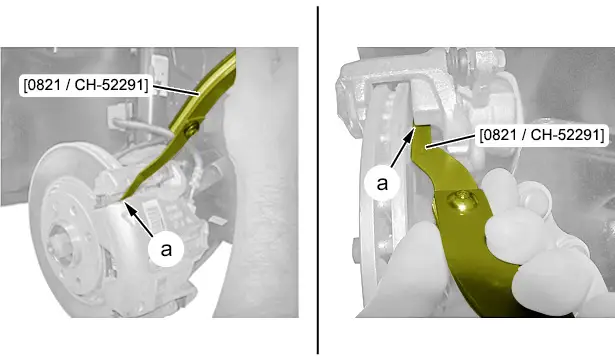

Check the wear of the brake pads : Using the tool [0821 / CH-52291].

N.B. : Take several measurements at the points accessible using the tool [0821 / CH-52291] (inside and outside) : For example at "a".

Correspondence between mm and % wear

| Thickness measured in mm | Equivalent percentage wear % |

| 2 mm | 100% |

| 3 mm | 90% |

| 4 mm | 80% |

| 5 mm | 70% |

| 6 mm | 60% |

| 8 mm | 40% |

| 10 mm | 20% |

| 12 mm | 0% |

Indicate the percentage wear on the form.

2.4. Under the vehicle

Visually check :

- The condition and routing of the parking brake cables

- That there are no leaks from the brake fluid pipes

- That there are no leaks from the compensator/limiter (According to equipment)

3. Recommendations following the check

Complete the form, indicating any comments, select the recommendations according to the results obtained.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image