Peugeot 308: Removing - refitting : Rear brake pads

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles(observe the regulations in force in the respective country).

N.B. : Symmetrical operations (right and left sides).

1. Tooling

Workshop equipment :

- Diagnostic tool

- Piston pushing tool

2. Preliminary operations

Place the vehicle on a 2-post lift.

CAUTION : Before carrying out any work on the rear braking components, place the rear motorised brake caliper actuator in the removal position ; Using the diagnostic tool.

CAUTION : If the brake fluid reservoir is at maximum level, remove its filter and partially drain the reservoir with the aid of a clean syringe in order to avoid it overflowing.

Place the rear motorised brake caliper in the removal position ; Using the diagnostic tool.

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries(depending on equipment).

Remove the rear wheels.

3. Removing

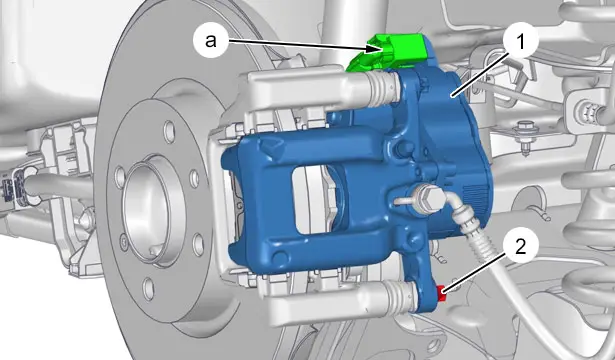

Disconnect the connector(at "a").

Close rear motorised brake caliper (1) actuator connector ; Using cleanliness plugs(depending on equipment).

Remove the bolt (2).

CAUTION : Do not twist the brake hose .

N.B. : Do not open the braking circuit on the brake caliper.

CAUTION : Limit the risk of knocks to the rear motorised brake caliper assembly actuator .

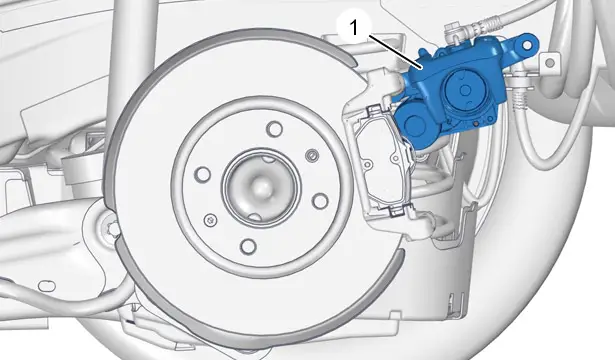

Tilt the rear brake caliper (1).

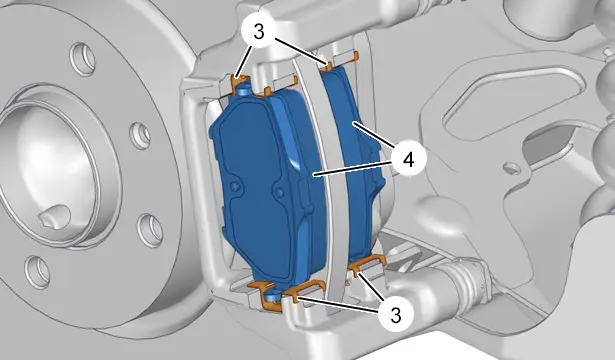

Remove :

- The brake pads (4)

- The sound-deadening pads (3)

4. Cleaning

CAUTION : Do not use compressed air to clean the brakes.

4.1. First possibility

Clean the brake disc and the brake caliper, using an approved brake cleaning product.

Leave to drip dry.

Wipe with a paper towel :

- The brake disc

- The rear motorised brake caliper (1)

4.2. Second possibility

Use dust removal equipment approved by the manufacturer .

5. Check

Visually check :

- The sealing around the rear motorised brake caliper (1) piston

- That the protective gaiters are in good condition and correctly adjusted

- The wear of the brake discs

Replace any defective parts.

CAUTION : No trace of grease, oil or lubricant can be tolerated on the brake pads.

6. Refitting

CAUTION : Observe the tightening torques.

ELECTRIC DRIVE TRAIN

Tightening torques :

- Braking system

- Wheels

CAUTION : Limit the risk of knocks to the rear motorised brake caliper assembly (1) actuator .

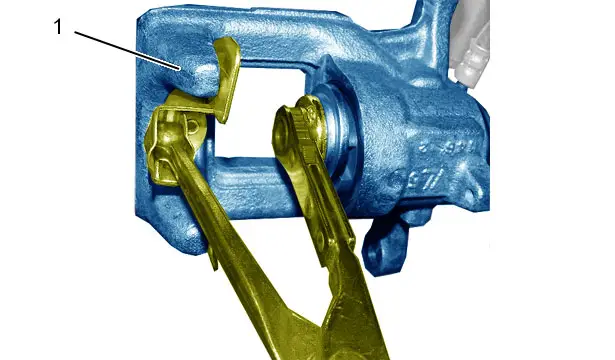

CAUTION : Do not turn the rear motorised brake caliper (1) piston to push it back.

Push back the rear motorised brake caliper piston (1) ; Using a piston pushing tool.

Check the brake fluid level.

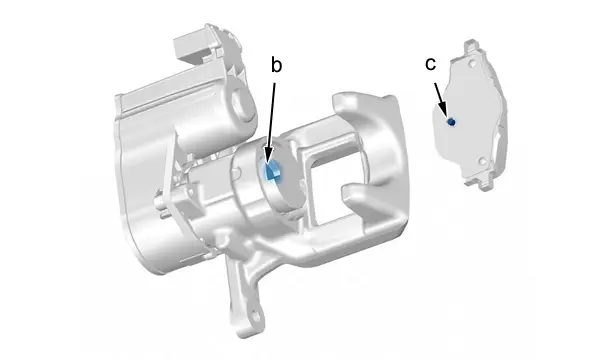

CAUTION : Make sure that the positioning lug (at "c") on the brake pad engages correctly in the recess (at "b") of the piston.

Refit :

- The sound-deadening pads (3) (New )

- The brake pads (4)

Put the rear motorised brake caliper assembly (1) in place.

CAUTION : The brake caliper bolts (2) are not always replaced with new bolts ; If the bolts (2) are reused, clean the thread and apply thread lock index "E3"

.

.

Refit the bolt (2).

Reconnect the connector (at "a").

7. Additional operations

Refit :

- The rear wheels

- The vehicle to its wheels

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries(depending on equipment).

Read and clear the fault codes ; Using the diagnostic tool.

ESSENTIAL : Apply the brakes several times, gently and progressively, with the engine running, before driving the vehicle.

Check the effectiveness of the braking.

Check the brake fluid level and top up if necessary.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image