Peugeot 308: Rezincing : Steel panels

1. PROTECTION OF THE PANELS DURING MANUFACTURE

The vehicles have numerous steel panels coated with a layer of zinc.

During manufacture, this zinc coating is applied either by galvanisation or by electroplating.

The zinc coating may be applied to the 2 faces or to one face only (Refer to the corresponding synopsis of vehicle parts ).

All of the exterior components and most of the structure parts have a layer of zinc on both faces of the panels.

The zinc coating can be destroyed in numerous instances :

- Deep scratches

- Straightening operations

- Welding operations when replacing parts

2. Repair

In order to obtain on repair a quality which is as close as possible to the original, this layer of zinc must be re-applied in the areas in which it has been destroyed following straightening or welding operations and in the case of deep scratches.

2.1. Protection of the internal face of the panels before spot welding

The internal protection of the welded joints must be carried out in all cases by rezincing and then by the application of a layer of conductive weldable paint (Primer containing copper or zinc ).

CAUTION : The paint products used for the internal protection of the welding areas must never be used as an under coat before painting or as an underseal coating (Separation certain ).

2.2. Protection of the external face of the panels in the welding areas

All of the "external" welding areas must be protected by rezincing.

It is advisable to then apply the general painting process :

- Wash primer (Etch primer )

- Primer

- Finishing paint

2.3. Protection of hollow bodies

Following any welded component replacement operations, it is imperative that protective wax is sprayed into the hollow sections concerned.

3. Workshop equipment

3.1. "DALIC" rezincing unit

3.2. 9008-T zincing unit

Composition of the provision made for the network in 1989 (No longer appears in the catalogue ) :

- Generator (Supply current : 220 Volts ; Secondary current : 12 Volts )

- 100 millimetre diameter anode for treating large surfaces (Planes with only slight curvature )

- 50 millimetre diameter anode (No longer appears in the new composition )

- 13 millimetre diameter anode (For small surfaces, difficult to access, welds )

- Pad holder for 50 and 100 millimetre diameter anodes

- Adaptor for 50 and 100 millimetre diameter anodes

- "red" supply lead for + current

- "black" supply lead for - current

- Plastic receptacle

- Caps for 13 millimetre diameter anodes

- Caps for 50 millimetre diameter anodes

- Caps for 100 millimetre diameter anodes

- Zincing solution N

- Instructions

4. Method of operation

4.1. Preparing the surfaces to be rezinced

Strip back.

"dry" sand with 280 paper.

Remove dust and grease using a non-oily solvent (Use a "pre-painting" degreaser ).

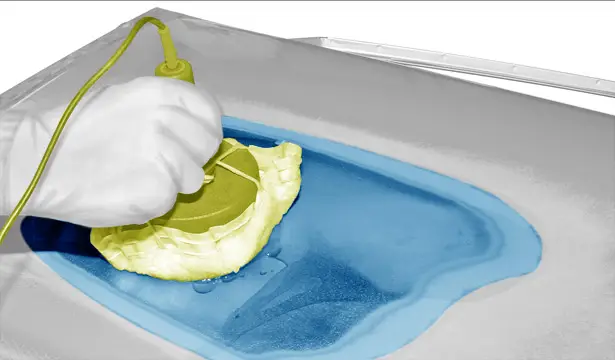

4.2. Putting the zincing unit into service

ESSENTIAL : When handling the zincing product and during its application, the operator must be equipped with a pair of impermeable plastic gloves and protective goggles.

Perform the following operations :

- Connect the generator to a 220 volt power socket

- Connect the supply leads

- Black lead (earth) between the part and the negative terminal (black) of the generator

- Read lead between the pad-holder and the positive terminal (red) of the generator

- Moisten the chosen cap with water to facilitate its impregnation with zincing solution N, before fitting it on the anode

- Screw the anode onto the pad-holder and fix the cap

- Pour a little zincing solution N into the plastic receptacle and place the anode with its cap in it

- Set the current regulator potentiometer to position 6 (In the case of rezincing unit B )

- During application, the ammeter indicates 20 amps (This setting permits even application )

5. Applying the zinc

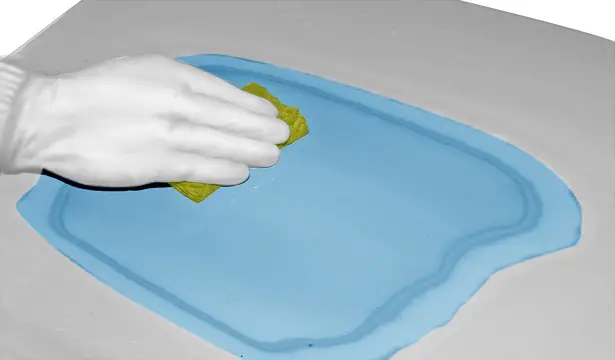

Sweep the surface to be treated several times, using the pad and cap assembly.

CAUTION : Never leave the pad immobile without a sweeping movement.

The surface changes colour, a sign of the application of zinc.

A 10 micron thick deposit is required.

To obtain a 10 micron thick deposit, a surface area of 1 square decimetre must be swept for 2 minutes.

N.B. : Average consumption of zincing solution N : 1 litre for 1 square metre.

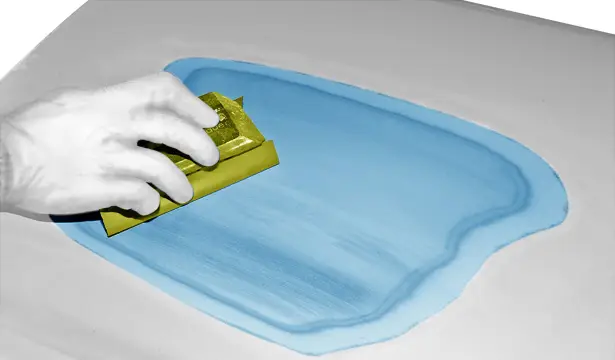

6. Cleaning the zinced surfaces

Rinse the treated surface thoroughly using a sponge moistened with tap water.

Wet sand using super fine abrasive paper (Grade 1000 or 1200 ).

Wipe and dry the surface.

7. Painting

Painting must be carried out as soon as possible after zincing to avoid any surface oxidation (Otherwise re-sand ).

8. Comments

The anodes must be sanded regularly using abrasive paper to guarantee good electrical conduction.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image