Peugeot 308: Removing - refitting : Supplies protection and management unit

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles(observe the regulations in force in the respective country).

1. Parts which must always be replaced

| Description | Quantity |

| Nut (Electrical harness (Supplies protection and management unit) ) | 1 |

| Nut (Electrical harness (Ancillaries battery 1 switch) ) | 1 |

2. Tooling

Workshop equipment :

- 1Plastic cap

- 1Adhesive paper tape

| tool | Reference | Description |

| [1603-3] (*) | Torque wrench adjustable from 5 to 25 Nm |

| (*) Use standard workshop equipment if the special tool is not available | ||

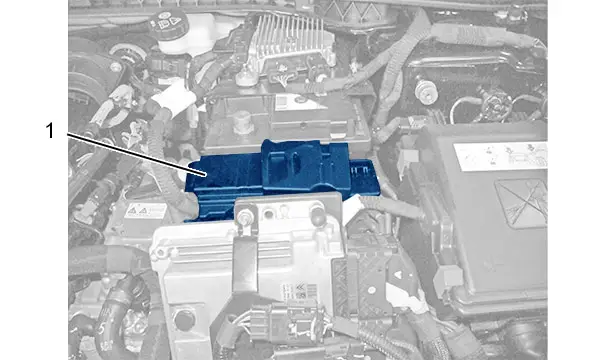

3. Location

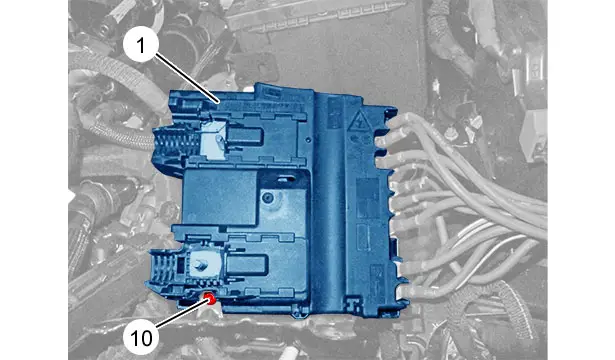

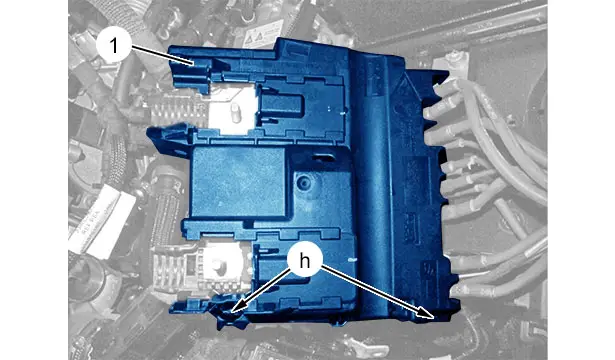

(1) Supplies protection and management unit (BPGA).

N.B. : The supplies protection and management unit (1) is installed in front of the ancillaries battery 1.

N.B. : The electrical supplies protection and management ECU permits cutting off of the electrical supply to maintain the safety of the vehicle in the event of a short circuit.

N.B. : The two faces of the supplies protection and management unit have electrical connections.

4. Preliminary operations

PHEV DRIVE TRAIN

CAUTION : Perform the operations that are required before disconnecting the ancillaries batteries

.

.

Disconnect the ancillaries batteries

(Following the specific procedure).

(Following the specific procedure).

Remove the engine management ECU

.

.

5. Removing

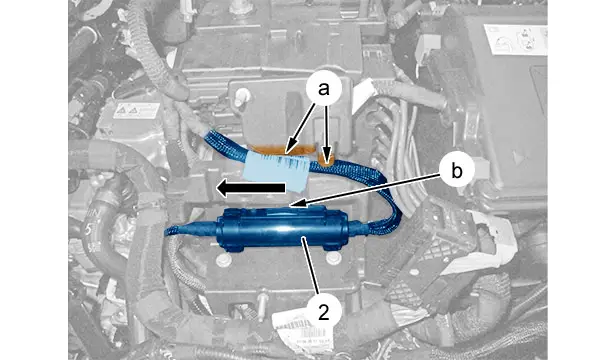

Unclip the electrical harness (at "a").

Unclip the fuse holder (2)(at "b")(in the direction of the arrow ).

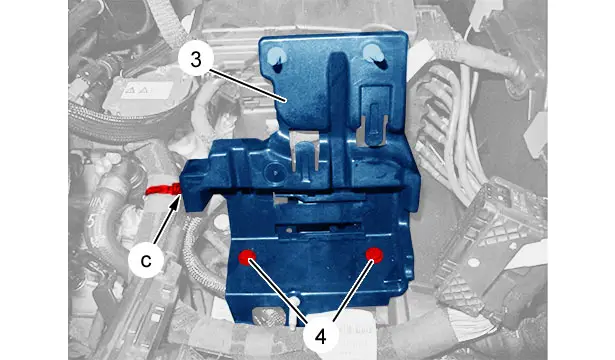

Unclip the electrical harness (at "c").

Remove :

- The 2 bolts (4)

- The support (3)

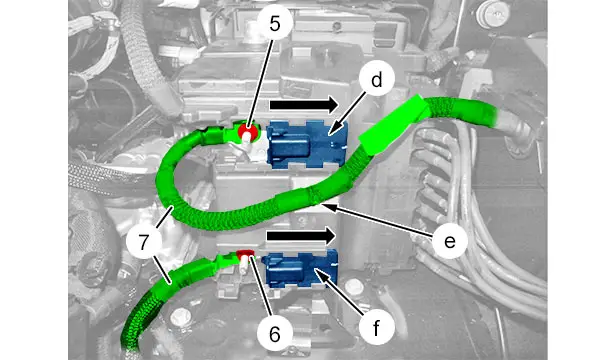

Unclip the electrical harness (7)(at "e").

Open the supplies protection and management unit (1) flaps (at "d", "f") (In the direction of the arrows ).

Remove the 2 nuts (5), (6).

Move aside the electrical harness (7).

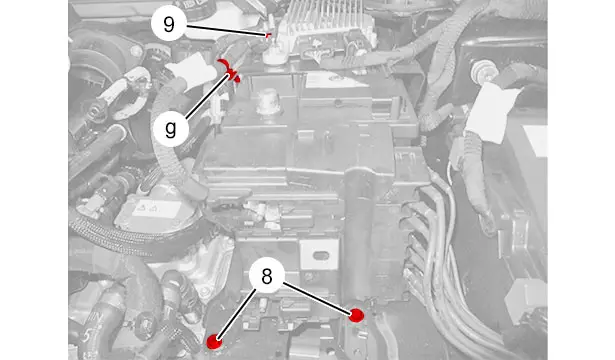

Unclip the electrical harness (at "g").

Remove :

- Nut (9)

- The 2 bolts (8)

Move aside the supplies protection and management unit (1) and its support (towards the top).

Remove the bolt (10).

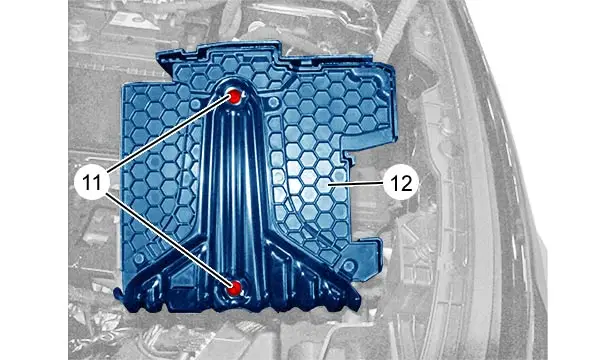

Remove :

- The 2 bolts (11)

- The supplies protection and management unit (1) support (12)

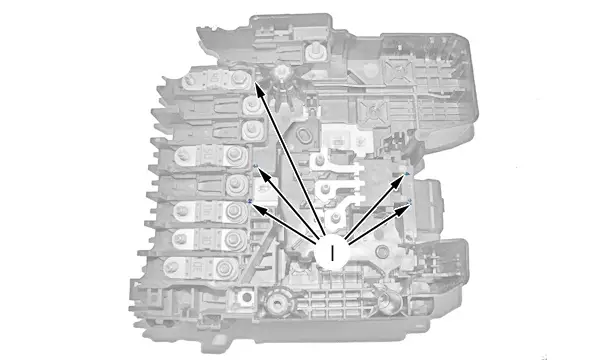

Lift the cover of the supplies protection and management control unit (1)(at "h").

6. Fuse reference

6.1. Front of vehicle

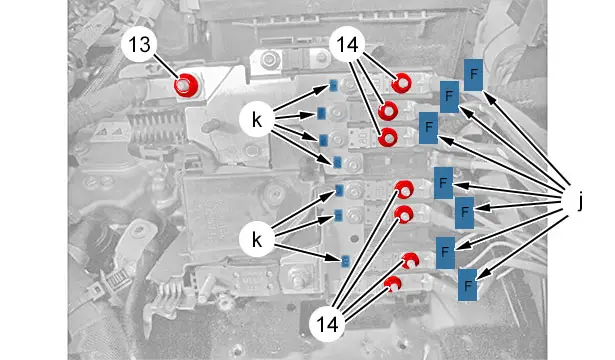

Remove the nut (13).

Disconnect and move aside the 1 ancillaries battery positive cable.

CAUTION : Identify and label each electrical wire with the corresponding fuse identification before disconnecting the supplies protection and management unit (Vehicle breakdown (or potential risk) ).

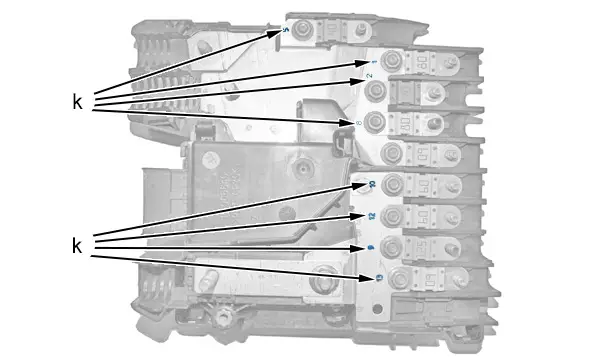

Label the wires (at "j") with the reference for the corresponding fuse(at "k") ; Using the adhesive paper tape.

N.B. : The number of fuses and wires varies according to the vehicle’s equipment.

Undo the nuts (14).

Remove the wires (Wire by wire).

6.2. Rear face

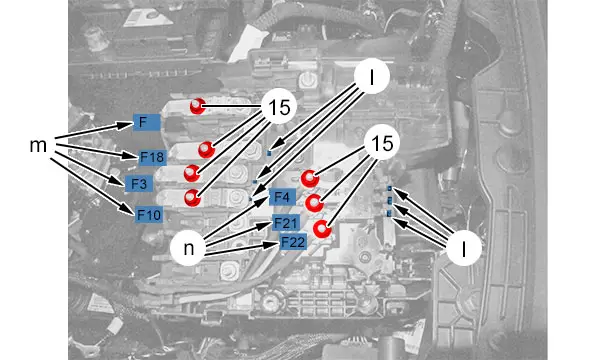

Label the wires (at "m", "p") with the reference for the corresponding fuse(at "l") ; Using the adhesive paper tape.

N.B. : The number of fuses and wires varies according to the vehicle’s equipment.

Undo the nuts (15).

Remove :

- The wires (Wire by wire)

- The supplies protection and management unit (1)

7. Refitting

PHEV DRIVE TRAIN

CAUTION : Observe the tightening torques

(Vehicle breakdown (or potential risk) ).

(Vehicle breakdown (or potential risk) ).

7.1. Front of vehicle

CAUTION : Before refitting the nuts (14), ensure that the labels (at "j") match the marks (at "k").

Perform the following operations (Wire by wire) :

- Reconnect the electrical wires

- Refit the nuts (14) ; Using the tool [1603-3]

7.2. Rear face

CAUTION : Before refitting the nuts (15), ensure that the labels (at "m", "p") match the marks (at "l").

Perform the following operations (Wire by wire) :

- Reconnect the electrical wires

- Refit the nuts (15) ; Using the tool [1603-3]

Refit :

- The 1 ancillaries battery positive cable

- The new nut (13) ; Using the tool [1603-3]

- The electrical supplies protection and management unit (1) cover (at "h")

- The supplies protection and management unit (1) support (12)

- The 2 bolts (11)

- The bolt (10)

7.3. Refitting(continued)

Put the supplies protection and management unit (1) and its support (12) in place.

Refit :

- The 2 bolts (8)

- The new nut (9) ; Using the tool [1603-3]

Clip the electrical harness (at "g").

Refit :

- The electrical harness (7)

- The 2 nuts (5), (6)

Clip the electrical harness (7)(at "e").

Close the supplies protection and management unit flaps (at "d", "f").

Refit :

- The support (3)

- The 2 bolts (4)

Clip the electrical harness (at "c").

Clip the fuse holder 2(at "b").

Clip the electrical harness (at "a").

8. Additional operations

Refit the engine management ECU

.

.

PHEV DRIVE TRAIN

CAUTION : Perform the operations that are required after reconnecting the ancillaries batteries

.

.

Reconnect the ancillaries batteries

(Following the specific procedure).

(Following the specific procedure).

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image