Peugeot 308: Adjustment : Multifunction video camera (When stationary)

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : This procedure must be used each time the multifunction video camera or the windscreen is replaced.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Tooling

Workshop equipment :

- 2Plumb-lines

- A diagnostic tool

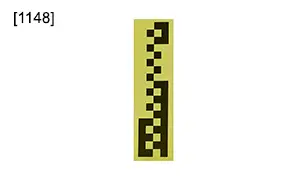

| Tool | Reference | Description |

| [1148] | Target |

| [1376-A] | Inclinometer |

2. Check

2.1. Prior conditions for checking

ESSENTIAL : Clean the exterior face of the multifunction video camera.

Check the condition of the windscreen.

Clean the windscreen.

Unload the vehicle.

Vehicle in running order (vehicle empty with all systems filled).

Remove any excessive accumulation of mud, snow or ice which could affect the ride height of the vehicle.

Check the tyre pressures.

Inflate to the pressure specified by the manufacturer, in normal driving conditions.

Park the vehicle on level ground, with the front wheels straightahead.

Set to the normal load position "O".

Set :

- The manual gearbox in neutral

- The automatic gearbox in position "N"

Release the handbrake..

2.2. Checking procedure

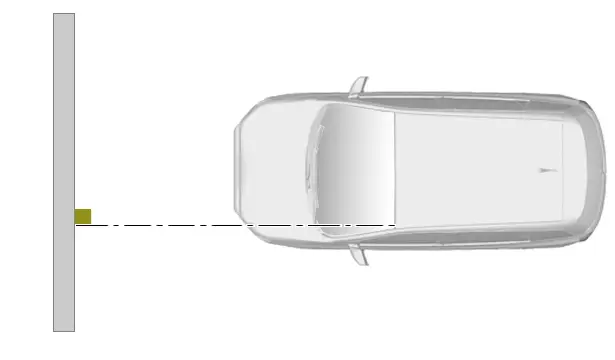

Place the vehicle in a perpendicular position (wheels straight) facing a wall of a light and uniform colour.

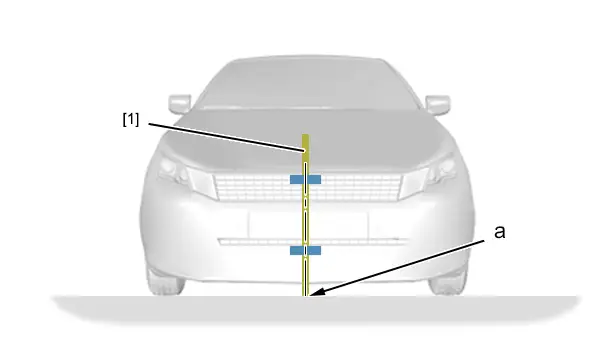

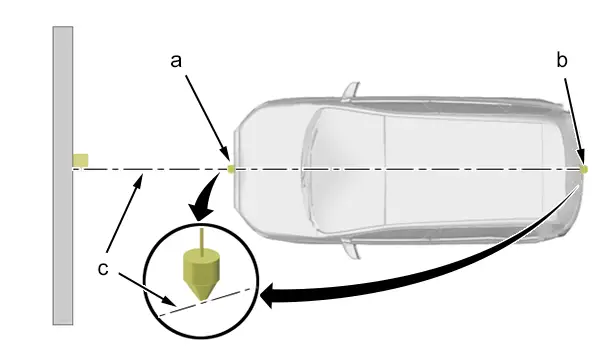

Position a plumb-line [1] in the centre of the vehicle ; Using an adhesive strip (Use the centre of the badge).

Mark the ground (at "a").

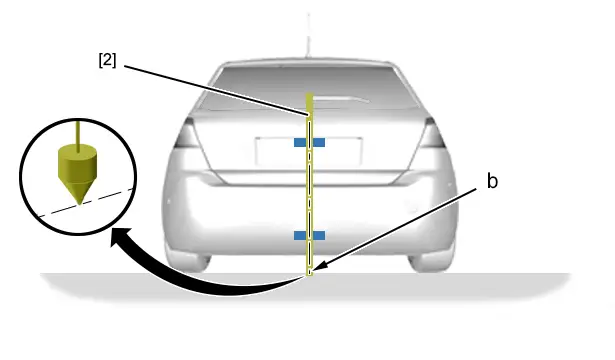

Position a plumb-line [2] in the centre of the vehicle ; Using an adhesive strip (Use the centre of the rear doors).

Mark the ground (at "b").

Mark the projection of the centreline of the vehicle (at "c") on the wall ; Using a cord passing through the points "a", "b".

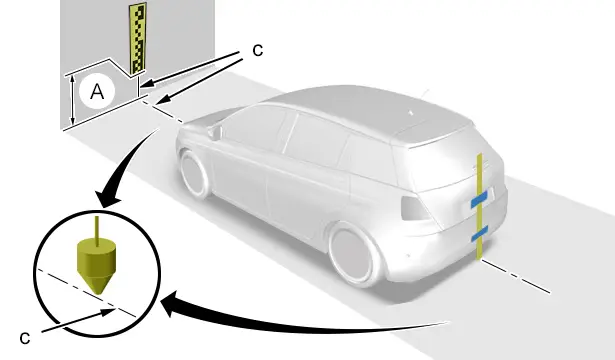

"A" = 900 mm.

Position the target vertically on the wall at a distance "A" from the ground, check that its centreline is aligned with the indication of the centreline of the vehicle on the ground (at "c").

Check that the target is vertical ; Using the inclinometer .

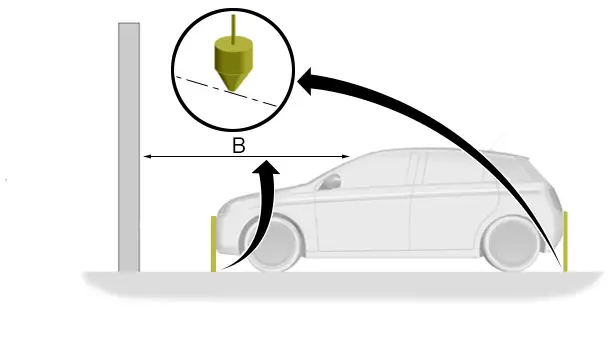

"B" = 1700 mm.

Move the vehicle forward to the distance "B" from the wall.

Check that the points are still aligned on the centreline of the vehicle (at "a" and "b").

Carry out the first phase of programming ; Using the diagnostic tool.

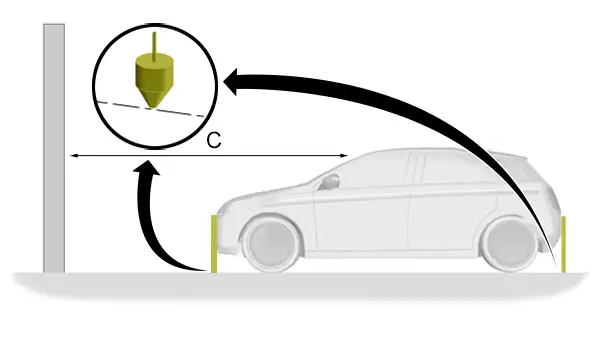

"C" = 2700 mm.

Move the vehicle back to the distance "C" from the wall.

Check that the points are still aligned on the centreline of the vehicle (at "a" and "b").

Carry out the second phase of programming ; Using the diagnostic tool.

N.B. : If the programming fails, carry out the procedure : Distance "B" = 2000 mm ; Distance "C" = Distance "B" x 1,6.

Example : Distance "B" = 2000 mm ; Distance "C" = 2000 x 1,6 = 3200 mm.

Move the vehicle forward to the distance "B" from the wall.

Check that the points are still aligned on the centreline of the vehicle (at "a" and "b").

Carry out the first phase of programming ; Using the diagnostic tool.

Move the vehicle back to the distance "C" from the wall.

Check that the points are still aligned on the centreline of the vehicle (at "a" and "b").

Carry out the second phase of programming ; Using the diagnostic tool.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image