Peugeot 308: Removing - refitting : (ABS/ESP) hydraulic block

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles(observe the regulations in force in the respective country).

1. Tooling

Workshop equipment : A diagnostic tool.

2. Preliminary operations

Place the vehicle on a 2-post lift.

CAUTION : Perform the operations that are required before disconnecting the ancillaries batteries

.

.

Disconnect the ancillaries batteries

(Following the specific procedure ).

(Following the specific procedure ).

Drain the braking circuit

.

.

Remove the aircon duct

.

.

3. Removing

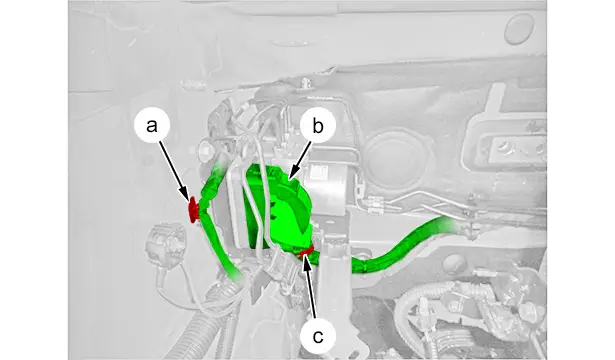

Unclip the electrical harness (at "a").

Disconnect the connector(at "b").

Unclip the electrical harness sheathing (at "c").

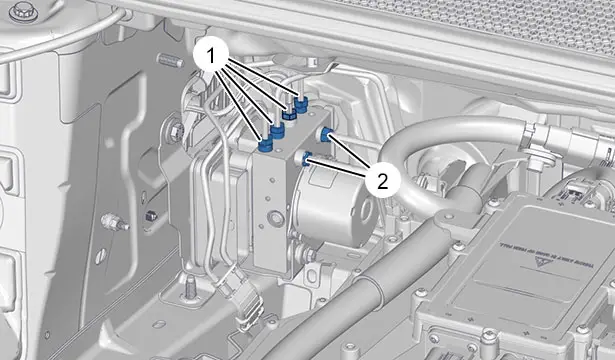

Loosen the brake pipe unions [ (1) and (2)].

N.B. : Prepare for the flow of brake fluid.

Remove the brake pipe unions [ (1) and (2)].

Move the brake pipes slightly away from the hydraulic block .

CAUTION : Plug the inlets and outlets of the hydraulic block to prevent any entry of foreign bodies.

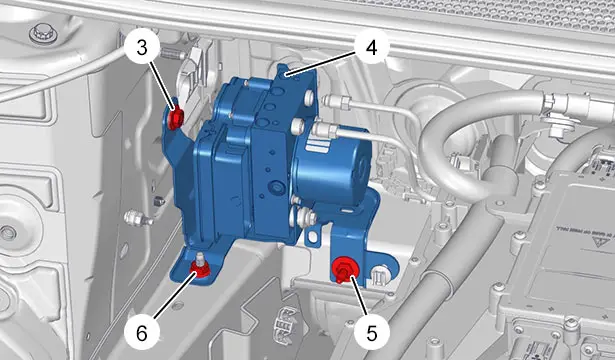

Remove :

- The bolts (3), (5)

- Nut (6)

- The hydraulic block - support assembly (4)

4. Refitting

CAUTION : Observe the tightening torques

.

.

CAUTION : Only remove the plugs from the connection openings of the hydraulic block when the brake pipes are fitted.

Refit :

- The hydraulic block - support assembly (4)

- The bolts (3), (5)

- Nut (6)

- Connectors (1) and (2)

Tighten unions ( 1) and (2).

Clip :

- The electrical harness (at "a")

- The electrical harness sheathing (at "c")

Reconnect the connector (at "b").

5. Additional operations

Fill and bleed the braking circuit

.

.

Refit :

- The air conditioning duct

- The vehicle to its wheels

CAUTION : Perform the operations that are required after reconnecting the ancillaries batteries

.

.

Reconnect the ancillaries batteries

(Following the specific procedure ).

(Following the specific procedure ).

6. Configuration of ECU

When replacing the hydraulic valve bock ; Using a diagnostic tool :

- Configure the ECU

- Calibrate the steering wheel angle sensor

- Calibrate the longitudinal acceleration sensor

- Read and clear the fault codes

CAUTION : Check the pressure of all the wheels before resetting the indirect tyre deflation detection system.

Adjust the pressure of the 4 tyres(if necessary).

Reinitialise the tyre under-inflation detection system ; Using the multifunction touch screen.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image