Peugeot 308: Removing - refitting : Electrical power harness

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

N.B. : Traction circuit : Traction battery electrical network.

1. Tooling

Workshop equipment : Insulating pads.

| Tool | Reference | Description |

| [01102] | Component lift |

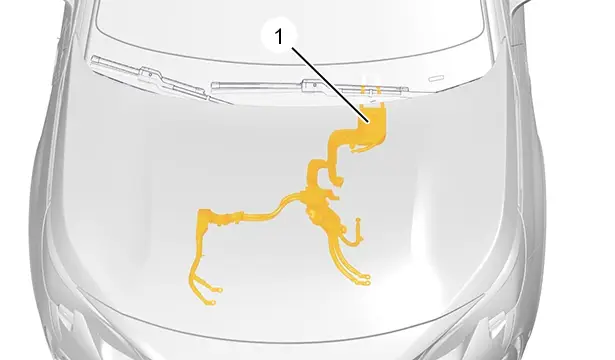

2. Location

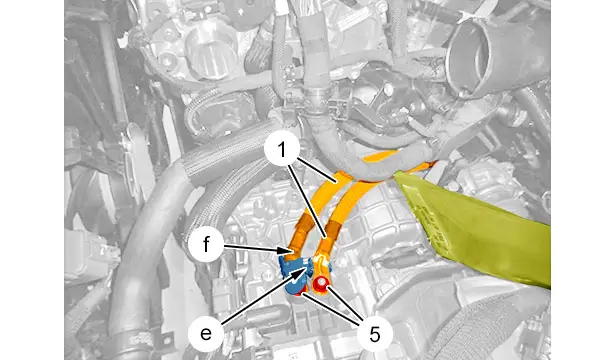

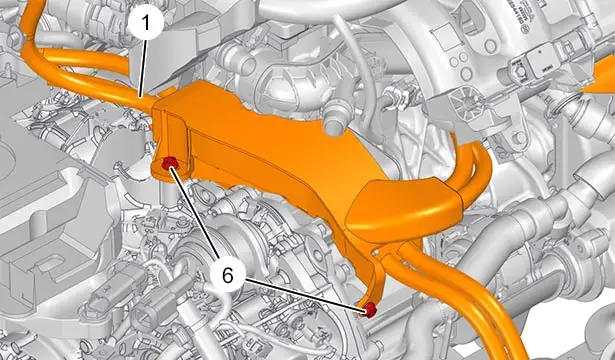

(1) Electrical power harness.

3. Preliminary operations

Place the vehicle on a 2-post lift.

ESSENTIAL : Switch the vehicle’s power off

.

.

Remove :

- The front right-hand wheel

- The front right-hand mudguard

- The protectors under the body

- The under-engine protector

- The ancillary drive belt protector

- The air filter housing

- The purge canister solenoid valve

4. Removing

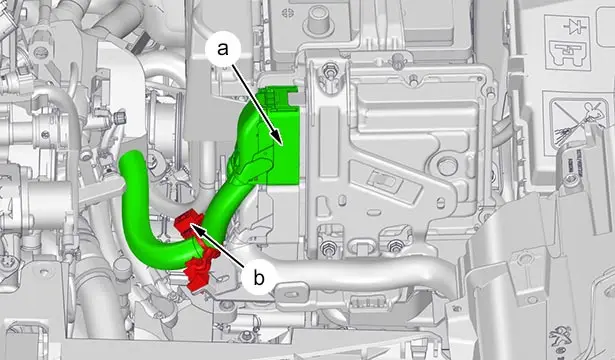

Disconnect the connector (at "a").

Unclip the electrical harness (at "b").

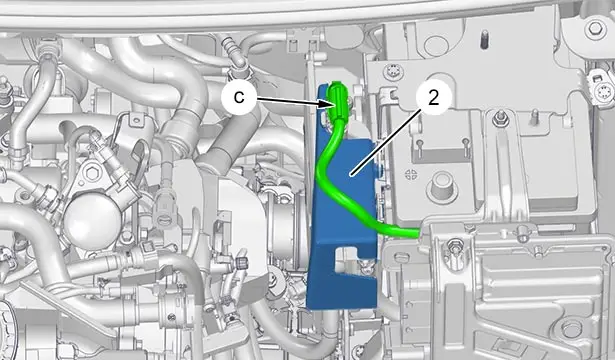

Disconnect the connector (at "c").

Remove the protector (2).

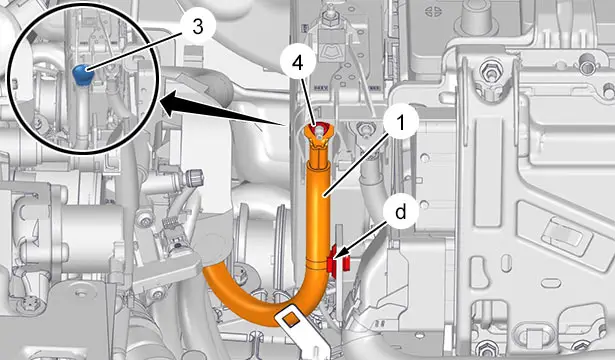

Remove :

- The closer (3)

- Nut (4)

Detach the electrical power harness (1) (at "d").

Move aside the electrical power harness (1).

ESSENTIAL : Place the electrical power harness (1) in an insulating bag.

Remove the ancillaries battery and its support

.

.

Unclip then move aside the protector (at "e").

Remove the 2 nuts (5).

Move aside the front electric drive machine inverter power connector .

ESSENTIAL : Place the electrical power harness (1) in an insulating bag (at "f").

Remove the bolts (6).

Move aside the electrical power harness (1).

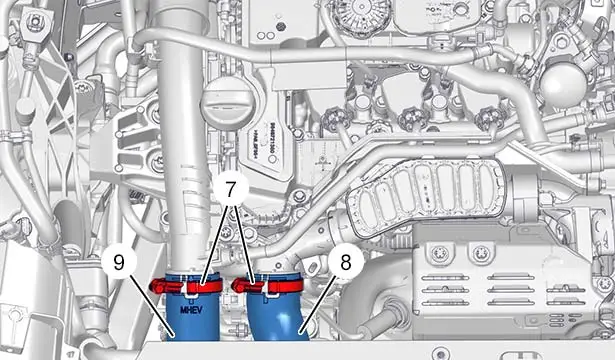

Slacken the clips (7).

Release :

- The air inlet union (8)

- The air outlet union (9)

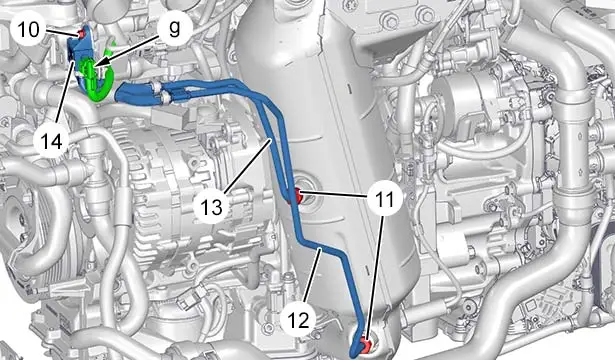

Slacken the 2 unions (11).

Move aside the pressure take-off pipes (12) and (13).

Disconnect the connector (at "g").

Remove :

- Nut (10)

- The particle filter differential pressure sensor (14)

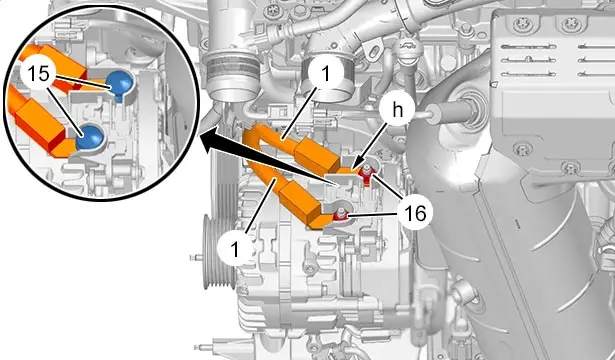

Remove :

- The plugs (15)

- The 2 nuts (16)

Detach the electrical power harnesses (1) .

ESSENTIAL : Place the electrical power circuit connector in an insulating bag (at "h").

CAUTION : Do not damage the electrical power harnesses (1).

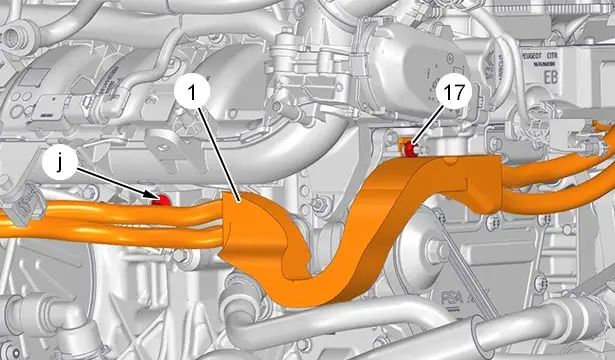

Remove the nut (17).

Detach the electrical power harnesses (1).

Unclip the (1) electrical harnesses (at "j").

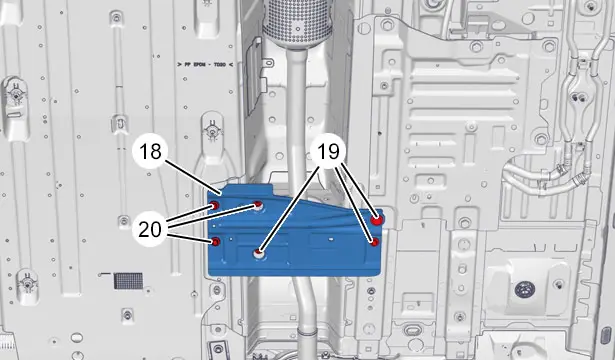

Remove :

- The bolts (19), (20)

- The tunnel strengthener (18)

CAUTION : Do not open the hybrid drive train cooling circuit.

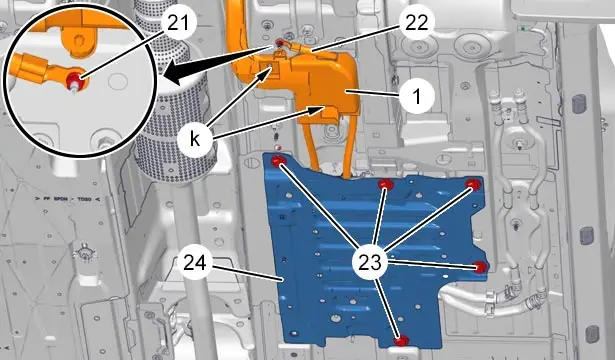

Remove :

- Nut (21)

- The earth cable (22)

Detach the electrical power harnesses (1) (at "k").

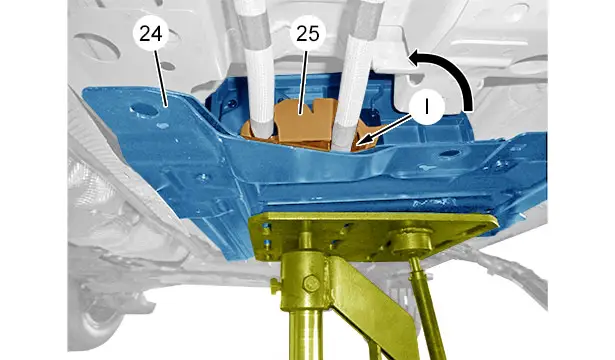

Place a component lift under the support and traction battery assembly (24).

Remove :

- The 5 bolts (23)

- The support and traction battery assembly (24) ; Using a component lift (Lower it a by a few centimetres only)

Support the support and traction battery assembly (24) ; Using a component lift.

Unclip then move aside the protector (25) (at "l").

CAUTION : Do not damage the electrical power harnesses (1).

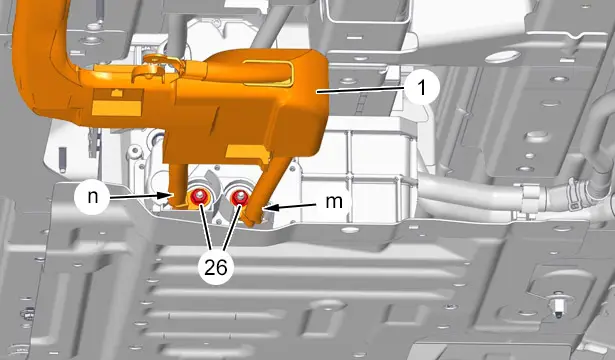

Remove the nuts (26).

Detach the electrical power harnesses (1) (at "m", "n").

Reclip the protector (25) (at "l").

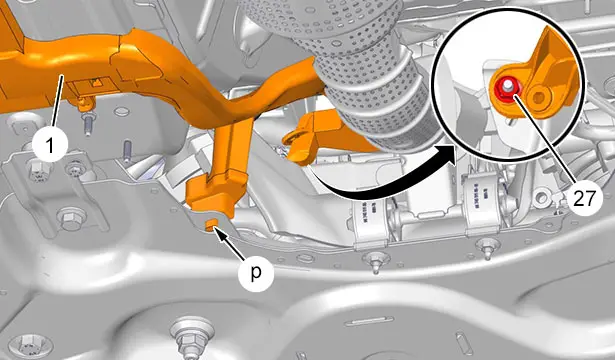

Remove the nut (27).

Detach the electrical power harness (1) (at "p").

Remove the electric power cable (1) (From below).

5. Refitting

MHEV DRIVE TRAIN

CAUTION : Observe the tightening torques.

Tightening torques :

- Components of the hybrid drive train

- Exhaust line

- Wheels

Refit the electrical power harness (1).

Clip the electrical power harness (1) (at "p").

Refit the nut (27).

Unclip then move aside the protector (25) (at "l").

Refit :

- The power harnesses (1) (at "m", "n")

- The nuts (26)

Reclip the protector (25) (at "l").

Refit :

- The support and traction battery assembly (24) ; Using a component lift

- The 5 bolts (23)

Clip the electrical power harness (1) (at "k").

Refit :

- The earth cable (22)

- Nut (21)

- The tunnel strengthener (18)

- The bolts (19), (20)

- The power harnesses (1) (at "j")

- Nut (17)

Remove the insulating bag (at "h").

Refit :

- The power harnesses (1)

- The 2 nuts (16)

- The plugs (15)

- The particle filter differential pressure sensor (14)

- Nut (10)

Reconnect the connector (at "g").

Couple the pipes (12), (13) on the pressure take-offs .

Tighten the unions (11).

Refit :

- The air inlet union (8)

- The air outlet union (9)

Tighten the clips (7).

Remove the insulating bag (at "f").

Refit :

- The bolts (6)

- The front electric drive machine inverter power connector

- The 2 nuts (5)

Reclip the protector (at "e").

Remove the insulating bag .

Refit the ancillaries battery and its support

.

.

Refit :

- The power harnesses (1)

- Nut (4)

- The closer (3)

Clip the electrical power harness (1) (at "d").

Refit the protector (2).

Reconnect :

- The connector (at "c")

- The connector (at "a")

Clip the electrical harness (at "b").

6. Additional operations

Refit :

- The purge canister solenoid valve

- The ancillary drive belt protector

- The air filter housing

- The front right-hand mudguard

- The front right-hand wheel

- The protectors under the body

- The under-engine protector

- The vehicle to its wheels

ESSENTIAL : Switch the vehicle’s power on

.

.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image