Peugeot 308: Removing - refitting : Engine ring seals

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Parts which must always be replaced

| Description | Quantity |

| Crankshaft seal ring (Flywheel side) | 1 |

| Crankshaft seal ring (Timing side) | 1 |

| Engine flywheel bolt | 6 |

| Ancillaries pulley bolt | 6 |

| Coolant pump drive belt | 1 |

2. Tooling

| Tool | Reference | Description |

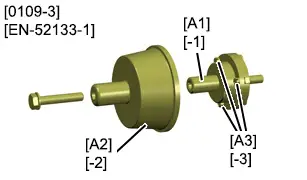

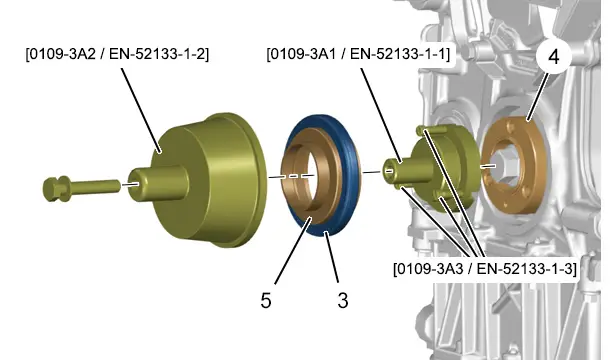

| [0109-3][EN-52133-1] | Crankshaft ring seal fitting drift (Timing side) |

| [0109-3A1][EN-52133-1-1] | Asembly guide | |

| [0109-3A2][EN-52133-1-2] | Seal fitting mandrel / Guide assembly bolt | |

| [0109-3A3][EN-52133-1-3] | Assembly guide tightening bolt | |

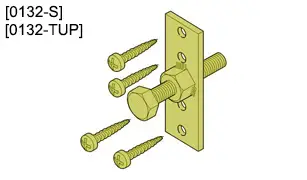

| [0132-TUP] (*) | engine repair kit |

| [0132-S] (*) | Ring seal extractor tool | |

| [0197-N][EN-52588] | Flywheel locking peg |

| (*) Use standard workshop equipment if the special tool is not available | ||

3. Crankshaft seal ring (Timing side)

3.1. Preliminary operations

Place the vehicle on a 2-post lift

.

.

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries (depending on equipment).

3.2. Removing

Remove :

- The ancillary drive belt

- The coolant pump drive belt

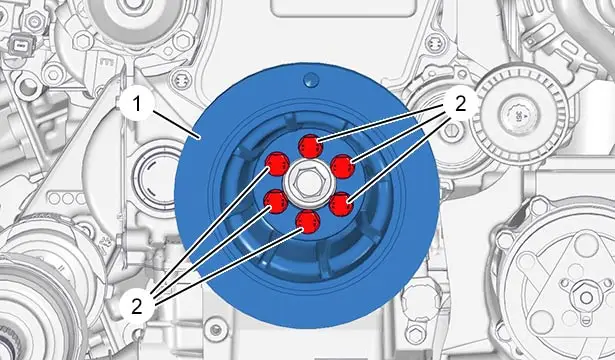

Remove :

- The 6 bolts (2)

- The crankshaft pulley (1)

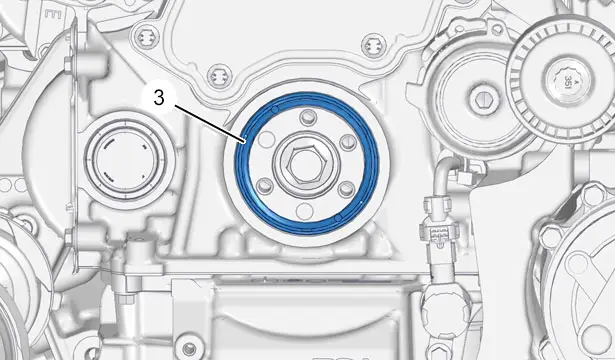

Remove the crankshaft sealing ring (3) (Timing side) ; Using the tool [0132-S].

3.3. Refitting

CAUTION : Observe the tightening torques

.

.

CAUTION : When the old ring seal has been removed, clean and degrease the housing in the cylinder block ; Using an approved degreasing product.

CAUTION : Before fitting a new ring seal the seal faces and surfaces must have no trace of impact nor scratches.

Refit ; Using the tool [0109-3 / EN-52133-1] :

- The fitting guide [0109-3A1 / EN-52133-1-1] onto the crankshaft hub (4) ; Using the 3 bolts [0109-3A3 / EN-52133-1-3]

- The sleeve (5) together with its new seal ring (3) on the crankshaft hub

- The tool [0109-3A2 / EN-52133-1-2] ; Using the bolt of tool [0109-3A2 / EN-52133-1-2]

Tighten the bolt of the tool [0109-3A2 / EN-52133-1-2] until the surface of the tool [0109-3A2 / EN-52133-1-2] comes into contact with the surface of the cylinder block .

CAUTION : The tool [0109-3A2 / EN-52133-1-2] has to stay in position for 30 seconds prior to removal.

Remove :

- The tools [0109-3A1 / EN-52133-1-1], [0109-3A2 / EN-52133-1-2], [0109-3A3 / EN-52133-1-3]

- The sleeve (5)

Refit :

- The crankshaft pulley (1)

- The (new) bolts (2)

- The new coolant pump drive belt

- The ancillary drive belt

- The vehicle to its wheels

3.4. Additional operation

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries(depending on equipment).

4. Crankshaft seal ring (Flywheel side)

4.1. Preliminary operations

Place the vehicle on a 2-post lift

.

.

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries(depending on equipment).

4.2. Removing

Remove :

- The engine - gearbox assembly

- The gearbox

Turn the engine clockwise by means of the crankshaft pulley screw, to bring it to the pegging position.

CAUTION : Peg the engine flywheel ; Using the tool [0197-N / EN-52588].

CAUTION : Never turn the crankshaft anticlockwise using the fixing bolt .

N.B. : Check that the engine is pegged correctly ; Turn the crankshaft clockwise using the pulley bolt .

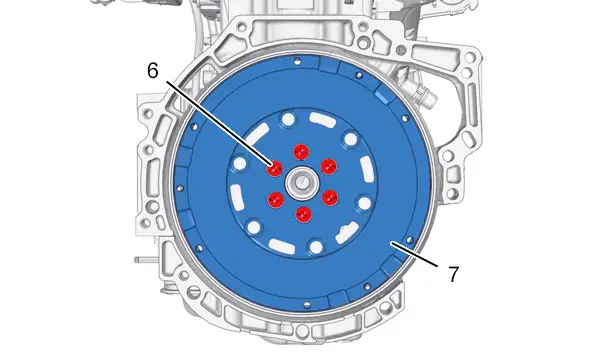

Remove :

- The 6 bolts (6)

- The engine flywheel (7) (depending on equipment)

- The tool [0197-N / EN-52588]

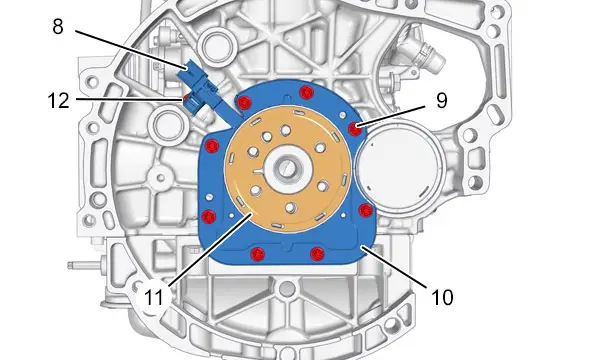

Remove :

- The magnetic target (11) of the engine speed sensor (8)

- The bolt (12)

CAUTION : Do not expose the engine speed sensor (8) to any source of magnetism.

Remove :

- The engine speed sensor (8)

- The 8 bolts (9)

- The closing plate (10) (The closing plate (10) is fitted with its sealing ring )

4.3. Refitting

CAUTION : Observe the tightening torques

.

.

CAUTION : After removing the old seal, clean and degrease the cylinder block contact surface ; Using an approved degreasing product.

CAUTION : Before fitting a new ring seal the seal faces and surfaces must have no trace of impact nor scratches.

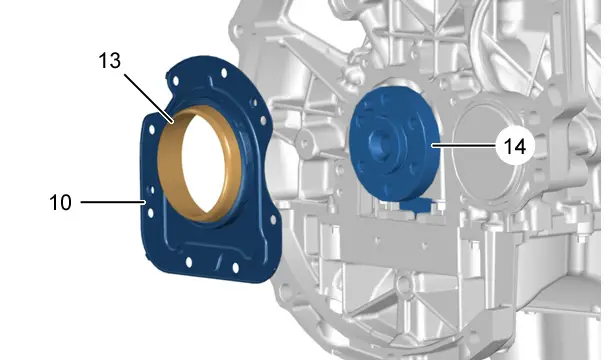

CAUTION : Dry and wipe the contact face of the crankshaft (14), using a high precision wiper(available from Replacement Parts).

N.B. : The new closing plate (10) has its own seal ring and positioning sleeve (13).

CAUTION : Do not lubricate the contact face of the seal ring.

Present the closing plate (10) with its positioning sleeve (13) on the crankshaft (14).

N.B. : The positioning sleeve (13) has to be centred on the crankshaft (14).

Push the closing plate (10) uniformly until it is in contact with the cylinder block.

Remove the positioning sleeve (13).

CAUTION : If the engine speed sensor (11) magnetic target (8) is removed or replaced, carry out an engine speed sensor (11) magnetic target (8) programming procedure.

Refit :

- The 8 bolts (9)

- The magnetic target (11) of the engine speed sensor (8)

- The engine speed sensor (8)

- The bolt (12)

- The engine flywheel (7)(depending on equipment)

- The (new) bolts (6)

Peg the engine flywheel ; Using the tool [0197-N/EN-52588].

Remove the tool [0197-N / EN-52588].

Refit :

- The gearbox

- The engine - gearbox assembly

4.4. Additional operation

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries (depending on equipment).

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image