Peugeot 308: Switching off : Hybrid vehicle

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

N.B. : Traction circuit: traction battery electrical network.

1. Tooling

1.1. Tooling

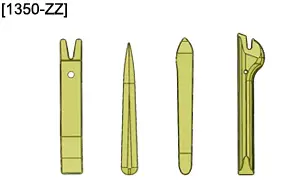

| Tool | Reference | Description |

| [VAT1] | Voltage absence verifier |

| [1350-ZZ] (*) | Stripping tools |

| (*) Use standard workshop equipment if the special too is not available | ||

1.2. Workshop equipment

An insulating pad.

Insulating pads.

Warning notices (Vehicle and work location).

Locking discs.

Adhesive tape (Orange).

Safety padlock.

1.3. Protective equipment

Insulating gloves (natural latex).

Hard hat with visor.

2. Preparation

Cut an insulating pad [1] of dimensions 15 X 15 cm.

N.B. : This operation only needs to be done once : The insulating pad can be used for other vehicles (depending on what condition it is in).

3. Switching off

3.1. Stage 1 : Vehicle identification - Sidelighting

CAUTION : Make sure that the vehicle indeed corresponds to the work order.

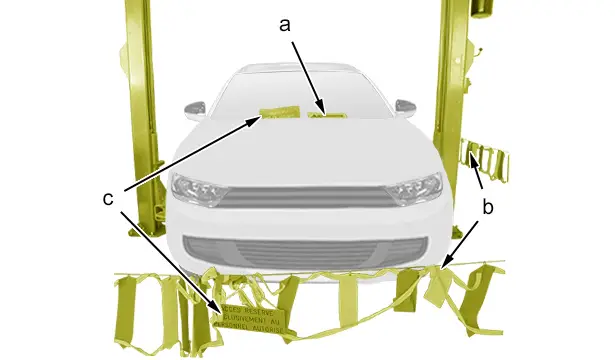

Place the vehicle in a work area dedicated to electric or hybrid vehicles.

N.B. : The work area must be separated off by chains or barriers (at "b").

Place the vehicle on a 2-post lift.

N.B. : In the absence of a 2-post lift : Place the vehicle on a 4-post lift. Immobilise the vehicle using workshop chocks (one on a front wheel and another on a rear wheel).

Fill in the work sheet, sign it and leave it on the vehicle’s windscreen (at "a").

Place the warning signs on the vehicle and on the work area (at "c").

Open :

- The door window (driver’s side)

- The boot lid

- The bonnet

Place the gear selection lever in position "P".

Apply the handbrake.

CAUTION : Check that the wheels cannot turn.

N.B. : Open the tailgate, because once the auxiliary network is switched off, the tailgate cannot be opened.

CAUTION : After switching off the ignition, wait for 5 minutes (Allowing the ECUs to go to sleep).

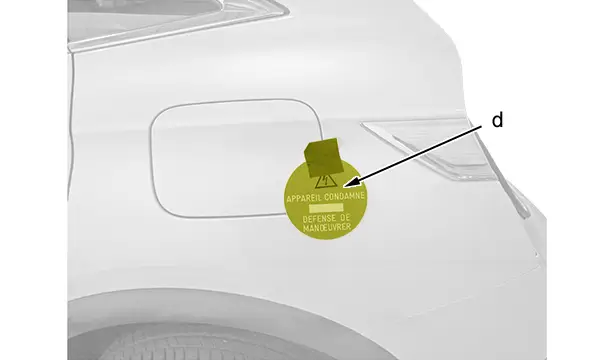

Attach a locking disc to lock the charging socket flap in the closed position (at "d").

3.2. Stage 2 : Electrical separation and locking (Ancillaries batteries)

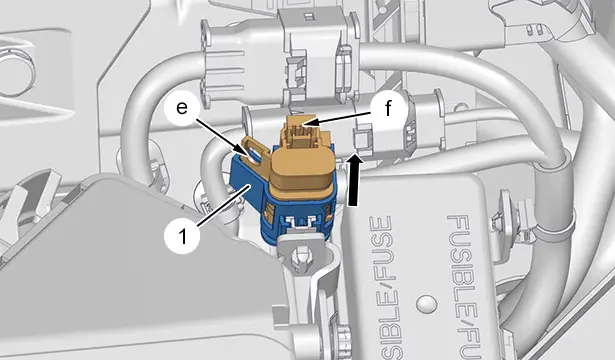

Deactivate the circuit breaker (1) (at "f") (In the direction of the arrow ).

Ensure that the circuit breaker (1) remains in the open position with a safety padlock (at "e").

ESSENTIAL : Store the circuit breaker padlock key with the vehicle key outside the vehicle.

Lift the boot carpet.

Unclip the plug (at "g") ; Using the tool [1350-ZZ].

Open the central armrest (at "h").

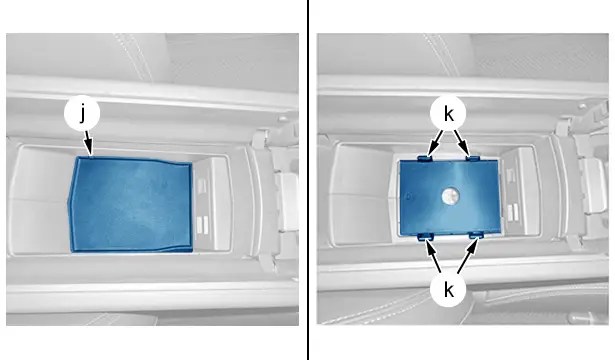

Remove the lining from the bottom of the storage compartment (at "j").

Unclip the ancillaries battery 2 flap cover (at "k").

ESSENTIAL : Put on insulating gloves and a hard hat with visor (visor lowered).

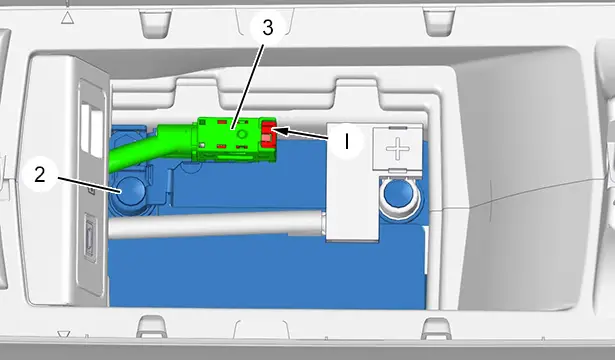

Unlock the negative terminal (3) of the ancillaries battery 2 (2) (at "l").

Disconnect the negative terminal (3) of the ancillaries battery 2 (2).

Place the ancillaries battery 2 (2) negative terminal (3) in an insulating bag (Use a tool or the battery pin to avoid any accidental contact with your hands).

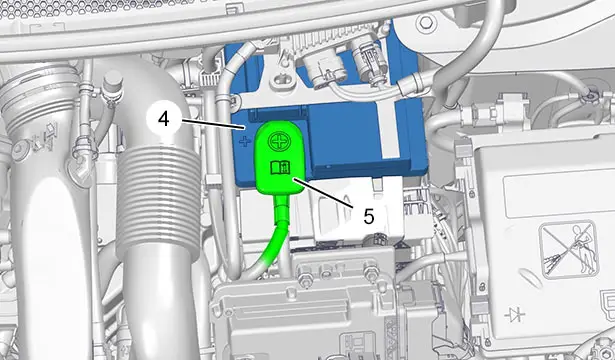

Disconnect the positive terminal (5) of the ancillaries battery 1 (4).

CAUTION : Wait for 2 minutes to discharge all network capacitors.

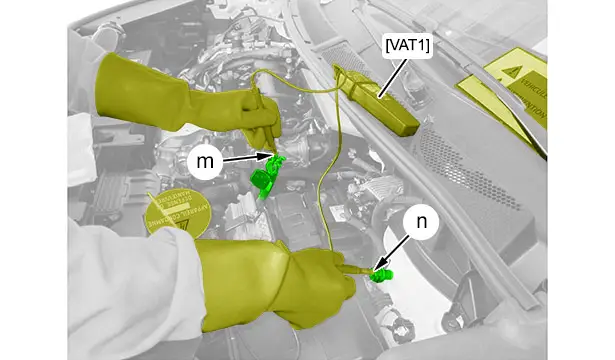

CAUTION : Check the voltage absence detector (Following the manufacturer’s instructions).

Check for the absence of voltage between the positive cable "m" that has been disconnected from the ancillaries battery 1 (4) and a body earth (at "n") ; Using the tool [VAT1].

N.B. : Check the voltage absence detector (Following the manufacturer’s instructions).

ESSENTIAL : In the event of a failure when checking for the absence of voltage, stop the switch-off procedure and escalate the issue to the work giver.

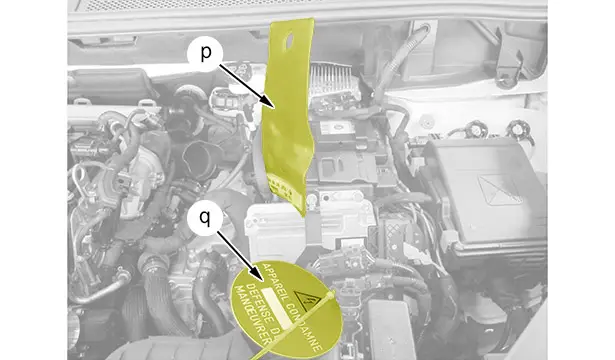

Put the ancillaries battery 1 (4) positive terminal in an insulating bag (at "p") (Use a tool or the battery pin to avoid any accidental contact with your hands).

Fit a locking disc (at "q").

3.3. Stage 3 : Electrical separation and locking (Traction battery)

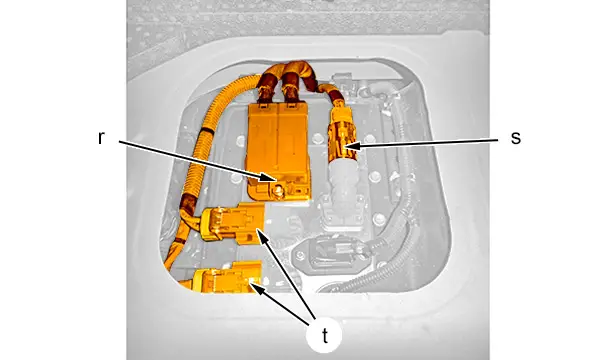

Disconnect the traction battery electrical power circuit connectors

(at "r", "s" and "t").

(at "r", "s" and "t").

Fit an insulating pad between the traction battery electrical power connectors and the traction battery (at "r", "s" and "t").

ESSENTIAL : Wait 2 minutes for all the filter capacitors of all the electrical power circuit components to discharge.

3.4. Stage 4 : Check for no voltage

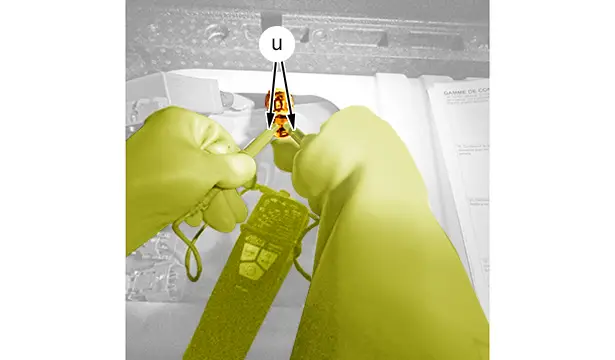

Check that there is no voltage between the pins of each traction battery power circuit connector (at "u") ; Using the tool [VAT1].

ESSENTIAL : The equipment probes must be in contact with the pins in the centre of the socket (at "u").

ESSENTIAL : In the event of a failure when checking for the absence of voltage, stop the switch-off procedure and escalate the issue to the work giver.

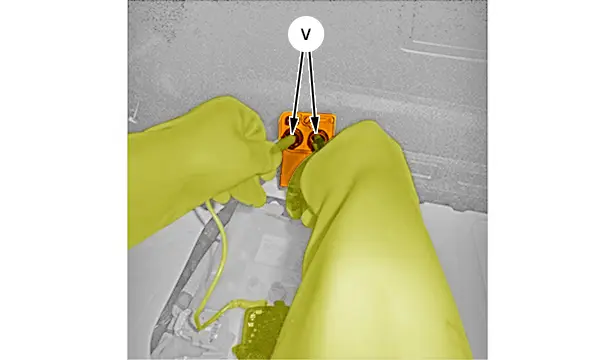

Check that there is no voltage between the pins of each traction battery power circuit connector (at "v") ; Using the tool [VAT1].

ESSENTIAL : The equipment probes must be in contact with the pins in the centre of the socket (at "v").

ESSENTIAL : In the event of a failure when checking for the absence of voltage, stop the switch-off procedure and escalate the issue to the work giver.

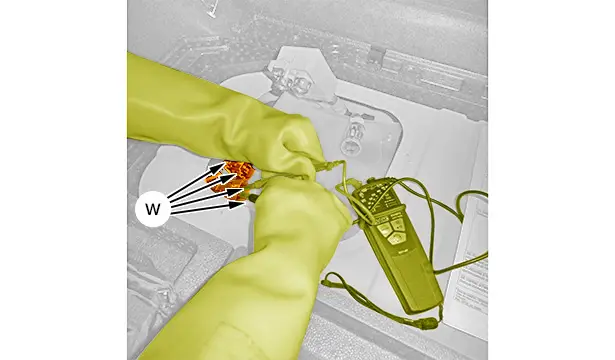

Check that there is no voltage between the pins of each traction battery power circuit connector (at "w") ; Using the tool [VAT1].

ESSENTIAL : The equipment probes must be in contact with the pins in the centre of the socket (at "w").

ESSENTIAL : In the event of a failure when checking for the absence of voltage, stop the switch-off procedure and escalate the issue to the work giver.

Place each traction battery electrical power circuit connector in an insulating bag (at "r", "s" and "t").

Remove the insulating pad between the traction battery electric power circuit connectors and the traction battery (at "r", "s" and "t").

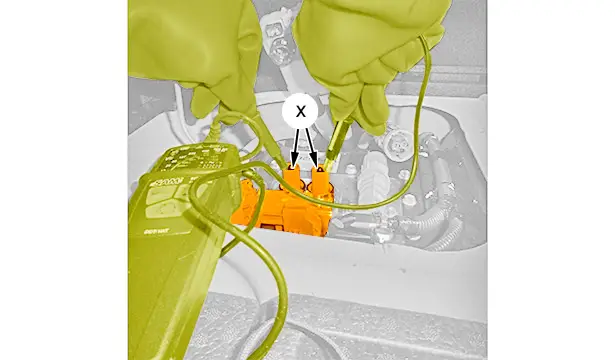

Check that there is no voltage between the pins of each traction battery power circuit connector (at "x") ; Using the tool [VAT1].

ESSENTIAL : The equipment probes must be in contact with the pins in the centre of the socket (at "x").

ESSENTIAL : In the event of a failure when checking for the absence of voltage, stop the switch-off procedure and escalate the issue to the work giver.

Fit an insulating pad between the traction battery electrical power connectors and the traction battery (at "r", "s" and "t").

ESSENTIAL : Remove your hard hat with visor and insulating gloves and complete the work sheet on the windscreen.

N.B. : The vehicle switch-off procedure is now complete and the vehicle is electrically secured.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image