Peugeot 308: Precautions to be taken : Engine - gearbox coupling

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

CAUTION : The use of an impact wrench is prohibited for all of the operations.

1. Replacement of parts in all cases

| Description | Quantity |

| Clutch mechanism bolt | 6 |

| Manual gearbox centring pins | 2 |

| clutch bearing (*) | 1 |

| Clutch release bearing guide (*) | 1 |

| Clutch fork (*) | 1 |

| Clutch fork ball joint (*) | 1 |

| Hydraulic clutch bearing (If removing/refitting the gearbox) | 1 |

| (*) If replacing the clutch mechanism or clutch disc | |

2. Clutch part

This document deals with the precautions to be taken when refitting a non-piloted manual gearbox.

2.1. Check of the wear of the clutch mechanism

Apply the method for checking the wear of the clutch disc with take-up of play

.

.

These checks concern the following points if refitting a used mechanism :

- Visual check of the wear marks

- No resetting of the clutch wear adjustment is permitted

- Check of the clutch disc friction plate, if there are any traces of grease or burns on the friction plate lining it must be replaced

2.2. Removing-refitting the clutch mechanism

Carry out the clutch mechanism removal-refitting method (pushed type)

.

.

Compliance with these instructions ensures the resolution of numerous gear engagement incidents.

Use the compression tool [0217] on removal if reusing the clutch mechanism.

Use of the compression tool [0217] is not necessary on removal if the clutch mechanism is to be replaced.

| Practices which do not conform | Cause | Consequences |

| Removal and refitting of the clutch mechanism without using the tool [0217] | Distortion of the take-up of play mechanism | De-adjustment of the take-up of play |

| Distortion and out-of-true of the diaphragm | Juddering, difficulty engaging gears, creaking of the clutch pedal | |

| Incorrect centring of the clutch disc | Difficulty engaging gears, rattling from the engine at idle and in neutral, destruction of the splines of the clutch disc |

2.3. Replacement of parts in all cases

If any fault is observed on one of the components of the clutch mechanism assembly, the following parts must be replaced :

- The clutch mechanism

- The clutch disc

- The clutch bearing

- The clutch mechanism fixing bolts

- The manual gearbox centring pins

2.4. Risks incurred by failing to replace the parts in all cases

| Part | Operations | Risks | Consequences |

| Mechanical clutch thrust bearing | When replacing the clutch mechanism | Wear of the diaphragm | Noise |

| Poor sliding of the mechanical clutch thrust bearing | Clutch pedal resistance | ||

| The hydraulic clutch bearing | For any removal - refitting of the gearbox with or without replacement of the clutch mechanism | Destruction of the seal due to slackening of the hydraulic clutch thrust bearing on a contaminated span | Leaking through the hydraulic clutch bearing |

| Manual gearbox centring pins | For any removal - refitting of the manual gearbox | Incorrect centring of the manual gearbox due to crushing of the centring pins and incorrect orientation | Incorrect working and wear of the clutch disc springs |

| Gear noise (rattling) as the acyclisms are no longer absorbed by the clutch disc springs | |||

| Breaking of the clutch disc springs | |||

| Incorrect centring of the friction plate in relation to the manual gearbox | Stiff gear changing due to poor sliding of clutch disc on the manual gearbox input shaft | ||

| Judder | |||

| Clutch mechanism bolt | For any refitting of the clutch mechanism | Lengthening of the mechanism bolts due to tightening beyond the elastic range | Breaking of the clutch mechanism bolts |

2.5. Fitting recommendations

| Operations | Recommendation | Consequences |

| Cleanliness and handling | Wash your hands before handling the clutch disc | clutch judder |

| Do not place your fingers on the clutch disc friction plate lining | ||

| Avoid any traces of oil or grease on the clutch disc friction plate lining | ||

| If there are any traces of oil or grease, the clutch disc must be replaced | ||

| Cleaning of the input shaft | Brush the splines of the input shaft using a metal brush to remove any traces of corrosion | Clutch disc travel incorrect |

| Lubrication of the input shaft splines | Compliance with the quality of the grease | Improved distribution of the grease on the splines of the input shaft |

| The recommended grease does not centrifuge and does not harden | ||

| No other grease is compatible with the hydraulic clutch thrust bearing seal | ||

| Compliance with the quantity of grease to be applied | Uniform distribution of the grease on the splines of the input shaft | |

| Greasing of the clutch disc hub | Distribution of the grease by sliding the clutch disc on the input shaft 5 or 6 times | Improved sliding of the clutch disc |

| Check of the presence of grease in the groove at the centre of the hub, add grease if lacking with the aid of a brush | Presence of a sufficient reserve of grease in the clutch disc hub | |

| Wiping off of the excess grease, using a clean cloth | Risk of splashes of grease |

N.B. : If reusing the clutch mechanism, make a mark on the clutch mechanism and on the engine flywheel to avoid any risk of imbalance.

3. Manual gearbox part

3.1. Replacement of parts in all cases

CAUTION : Incorrect centring of the manual gearbox causes a malfunction or destruction of the clutch.

| Description | Quantity |

| Manual gearbox centring pins | 2 |

3.2. Replacement of the manual gearbox centring pins

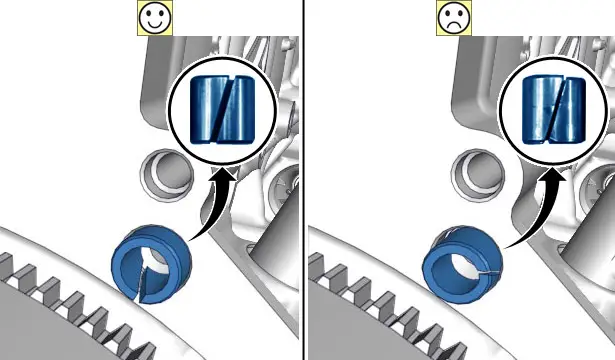

Replace the centring pins with new pins and observe the positioning of these before refitting the manual gearbox.

Always replace the centring pins on the cylinder block :

- Crushing of the split centring pins results in incorrect centring of the manual gearbox (clearance of the centring pins in their housings) and difficulty engaging gears

- It is imperative that the slot of the centring pins is positioned vertically

- Downwards vertical orientation of the slot of the centring pins to prevent any accumulation of moisture

3.3. Procedure for tightening the manual gearbox on the engine

Refit the manual gearbox .

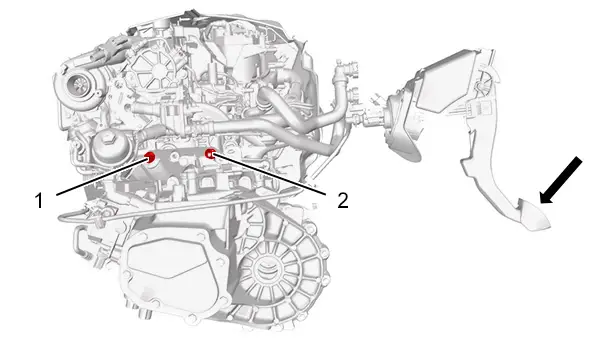

Support the gearbox in position and tighten the 2 nuts (2) closest to the centring pins.

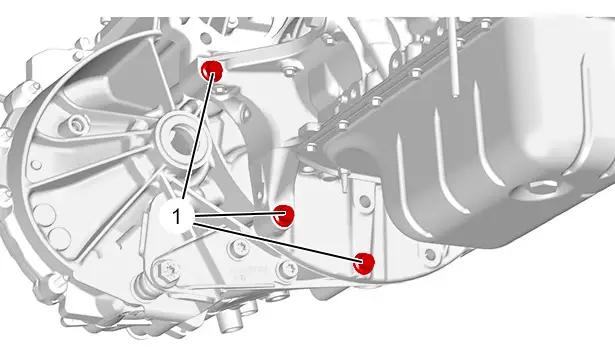

Refit the manual gearbox fixings (1).

Refit and bleed the hydraulic clutch control (3).

Refit the manual gearbox fixings (1).

Press the clutch pedal and hold it in this position.

N.B. : Operation requiring 2 operators or the use of a pedal press.

Slacken all the fixings (1), (2) by half a turn.

Tighten the manual gearbox fixings (1), (2).

Release the clutch pedal.

N.B. : This procedure permits the release of the friction plate and ensures correct alignment of the engine and the manual gearbox.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image