Peugeot 308: Check : Oil pressure

ESSENTIAL : Follow the safety instructions

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Parts which must always be replaced

| Description | Quantity |

| Oil pressure sensor seal | 1 |

2. Tooling

N.B. : The pressure gauge [1529] and the corresponding adaptor can be used in place of the pressure gauge indicated.

Workshop equipment :

- Insulation bag

- 6 mm diameter drill bit

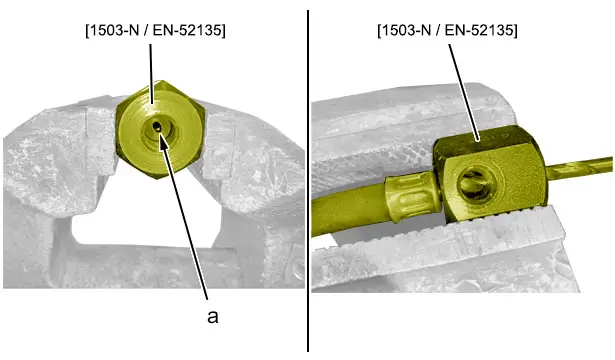

| Tool | Reference | Description |

| [1503-AY][KM-498-B] | Oil pressure gauge |

| [1503-B] (*) | Pressure take-off hose |

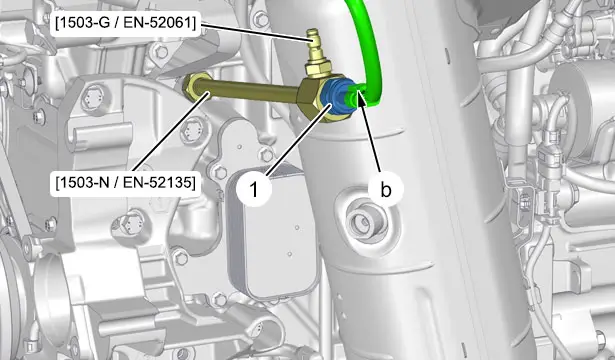

| [1503-N][EN-52135] | Engine oil pressure take-off union |

| [1503-G][EN-52061] | Pressure take-off end piece |

| (*) Use standard workshop equipment if the special tool is not available | ||

3. Prepare the tooling

CAUTION : After drilling, clean all the metal chips from the engine oil pressure take-off union [1503-N / EN-52135].

Place the tool [1503-N / EN-52135] in a vice.

Enlarge the opening for the flow of engine oil ; Using the 6 mm drill bit (at "a").

4. Preliminary checks

Prior to commencing the method for checking the oil pressure ; Make the following checks :

- The oil quality and level

- That there are no foreign bodies in the engine oil

CAUTION : Oil pressure is checked with the engine hot after checking the oil level.

5. Removing

Place the vehicle on a 2-post lift.

ESSENTIAL : Switch the vehicle’s power off

.

.

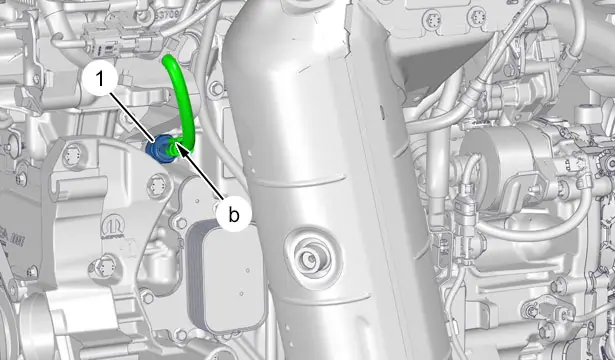

Disconnect the oil pressure sensor (1) connector

(at "b").

(at "b").

Remove the oil pressure sensor (1)

.

.

N.B. : Protect the surrounding area using a cloth on removal to absorb the oil which flows out of the opening.

5.1. Check

N.B. : Oil pressure is checked with the engine hot after checking the oil level.

Tighten :

- The tool [1503-N / EN-52135] on the cylinder block (Manually)

- The tool [1503-G / EN-52061] on the tool [1503-N / EN-52135]

- The oil pressure sensor (1) on the tool [1503-N / EN-52135]

Assemble the hose [1503-B] fitted with the pressure gauge [1503-AY / KM-498-B] on the end piece [1503-G / EN-52061].

Reconnect the oil pressure sensor (1) connector

(at "b").

(at "b").

ESSENTIAL : Switch the vehicle’s power on

.

.

Start the internal combustion engine .

CAUTION : Compare the pressure values read on the diagnostic equipment and on the pressure gauge [1503-AY / KM-498-B]. If there is a significant difference in pressure, replace the oil pressure sensor.

Compare the readings on the oil pressure gauge with those in the table

.

.

5.2. Refitting

CAUTION : Observe the tightening torques.

MHEV DRIVE TRAIN

Tightening torques :

- engine

- Wheels

Protect the surrounding area using a cloth on removal to absorb the oil which flows out of the opening.

ESSENTIAL : Switch the vehicle’s power off

.

.

Disconnect the oil pressure sensor (1) connector

(at "b").

(at "b").

Remove :

- The pressure gauge [1503-AY / KM-498-B]

- The flexible hose [1503-B]

- The oil pressure sensor (1)

- The tool [1503-G / EN-52061]

- The tool [1503-N / EN-52135]

Refit the oil pressure sensor (1) (complete with a new seal)

.

.

ESSENTIAL : Switch the vehicle’s power on

.

.

Return the vehicle to its wheels.

Check the engine oil level.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image