Peugeot 308: Check : Setting of the timing

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles (observe the regulations in force in the respective country).

1. Replacement of parts in all cases

| Description | Quantity |

| Bolt (Camshaft dephasers / Camshafts) | 2 |

2. Tooling

| Tool | Reference | Description |

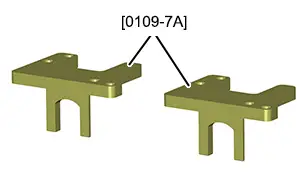

| [0109-7A] | Camshaft setting tool |

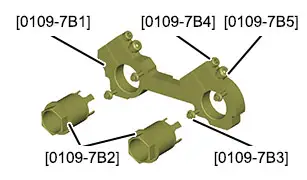

| [0109-7B] | Torque recovery tool for dephaser bolts |

| [0109-7B1] | Torque recovery plate | |

| [0109-7B2] | Torque recovery sockets | |

| [0109-7B3] | Torque recovery plate fixing bolt | |

| [0109-7B4] | Torque recovery plate sockets slackening bolt | |

| [0109-7B5] | Torque recovery plate sockets tightening bolt | |

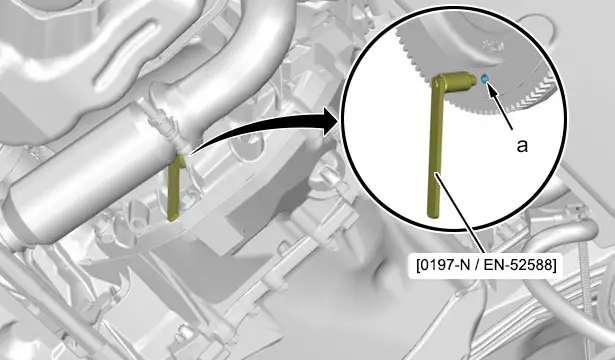

| [0197-N][EN-52588] | Crankshaft setting pin |

3. Checking the setting

CAUTION : Perform the operations that are required prior to a disconnection of the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Disconnect the ancillaries battery or batteries(depending on equipment).

Remove :

- The oil trap

- The camshaft dephasing solenoid valves

- The coil of cylinder N° 3

Rotate the engine slightly in a clockwise direction using the crankshaft pulley screw to bring it to the pegging position.

Peg the engine flywheel (In "a") ; Using the tool [0197-N / EN-52588].

N.B. : Check the pegging of the engine by trying to turn the crankshaft bolt clockwise and anti-clockwise.

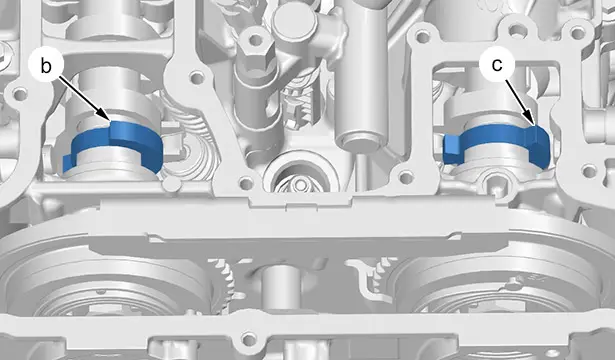

Observe the position of the targets (at "b" and "c") of the camshafts.

Otherwise, remove the tool [0197-N / EN-52588] and rotate the crankshaft once ; Peg the engine flywheel again (In "a").

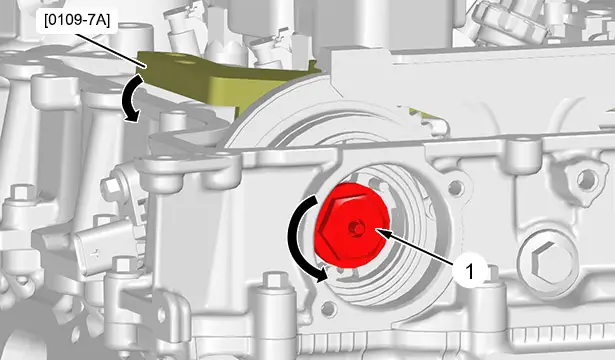

Position the tool [0109-7A].

Do not flush fit the tool [0109-7A] on the joint face of the camshaft carrier.

Apply a tightening torque of 2 daNm to the inlet camshaft dephaser bolt (1) in an anticlockwise direction ; The tool [0109-7A] must be fitted on the joint face of the camshaft carrier.

Tighten the tool fixing bolts [0109-7A] ; Using the 2 oil separator bolts.

Perform the following procedure : Check - setting the exhaust camshaft.

CAUTION : If the tool [0109-7A] is not correctly flush-fitted on the joint face of the camshaft carrier, move on to the section “slackening of the camshaft dephasers”.

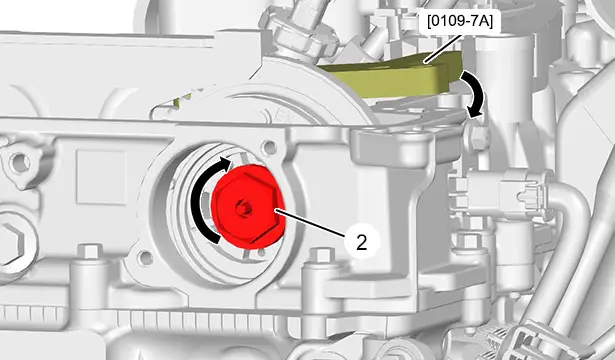

Position the tool [0109-7A].

Do not flush fit the tool [0109-7A] on the joint face of the camshaft carrier.

Apply a tightening torque of 2 daNm to the inlet camshaft dephaser bolt (2) in a clockwise direction ; The tool [0109-7A] must be fitted on the joint face of the camshaft carrier.

If the tool [0109-7A] is fitted correctly on the joint face of the camshaft carrier, the setting conforms ; Move on to the refitting operations.

CAUTION : If the tool [0109-7A] is not correctly flush-fitted on the joint face of the camshaft carrier, move on to the section “slackening of the camshaft dephasers”.

4. Slackening of the camshaft dephasers

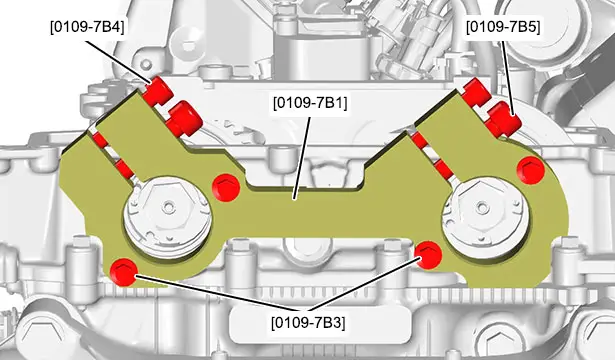

CAUTION : Observe the tightening torque for the fixing bolts [0109-7B3].

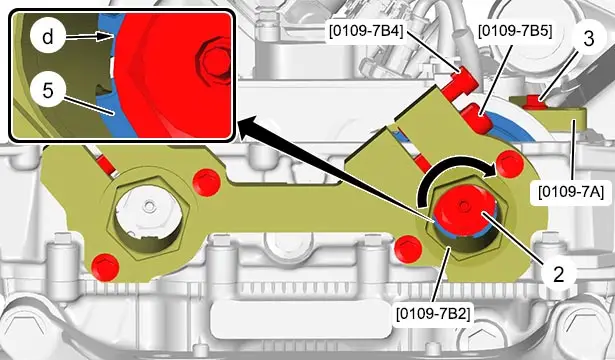

Position the tool [0109-7B1].

Torque tighten the fixing bolts [0109-7B3] to 0,8 daNm.

[0109-7B4] : Slackening bolt in the event of slight distortion of the tool [0109-7B3].

[0109-7B5] : Torque recovery plate sockets tightening bolt.

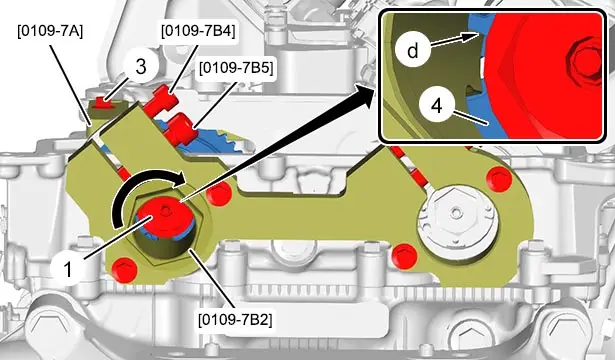

N.B. : Remove the tool [0197-N / EN-52588].

Rotate the crankshaft until the tool [0109-7A] is flush-fitted on the camshaft carrier.

Tighten the tool [0109-7A] ; Using the 2 bolts (3).

Engage and push the lugs of the tool [0109-7B2] fully into the notches of the inlet camshaft dephaser (4).

Manually turn tool [0109-7B2] clockwise and position the lugs fully in the notches of the inlet camshaft dephaser (4) (In "d").

Keep the lugs of the tool [0109-7B2] fully in (at "d") and torque tighten the bolt [0109-7BX] to 4 daNm.

N.B. : This operation is necessary in order to transmit the slackening force from the inlet camshaft dephaser (4) into the lugs of the tool [0109-7B2].

Remove the bolt (1).

Fit the new bolt (1) by hand(without tightening).

Slacken the tightening bolt [0109-7B5] to release the tool [0109-7B2] ; Do not release the lugs of the tool [0109-7B2] from the inlet camshaft dephaser (4).

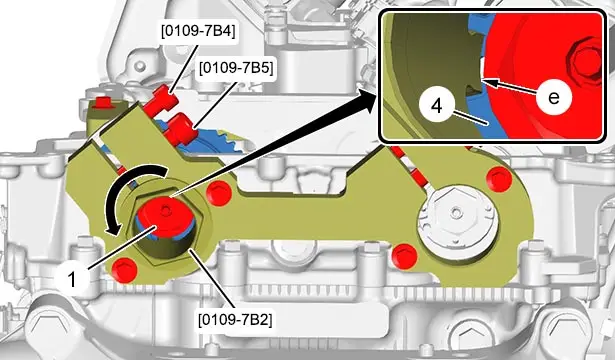

Rotate the crankshaft until the tool [0109-7A] is flush-fitted on the camshaft carrier.

Tighten the tool [0109-7A] ; Using the 2 bolts (3).

Engage and push the lugs of the tool [0109-7B2] fully into the notches of the exhaust camshaft dephaser (5).

Manually turn the tool [0109-7B2] clockwise and position the lugs fully in the notches of the inlet camshaft dephaser (5) (In "d").

N.B. : The tightening bolt [0109-7BX] must be slackened.

Keep the lugs of the tool [0109-7B2] fully in (at "d") and torque tighten the bolt [0109-7BX] to 4 daNm.

N.B. : This operation is necessary in order to transmit the slackening force from the exhaust camshaft dephaser (5) into the lugs of the tool [0109-7B2].

Remove the bolt (2).

Fit the new bolt (2) by hand(without tightening).

Slacken the tightening bolt [0109-7B5] to release the tool [0109-7B2] ; Do not release the lugs of the tool [0109-7B2] from the exhaust camshaft dephaser (5).

5. Tightening of the camshaft dephasers

CAUTION : Observe the tightening torques

.

.

Peg the engine flywheel (In "a") ; Using the tool [0197-N / EN-52588].

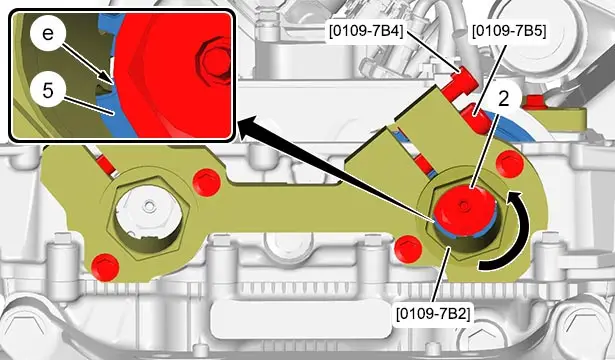

N.B. : The slackening bolt [0109-7B4] must be slackened.

Apply a tightening torque of 2 daNm to the tool [0109-7B2] in an anticlockwise direction.

N.B. : This operation is necessary in order to retension the timing chain and transmit the tightening force of the inlet camshaft dephaser (4) to the lugs of the tool [0109-7B2] (In "e").

Keep the lugs of the tool [0109-7B2] fully in (at "e") and torque tighten the bolt [0109-7B5] to 4 daNm.

Tighten the new bolt (1).

Manually turn tool [0109-7B2] anticlockwise, hold the lugs fully in (at "e") and torque tighten the bolt [0109-7B5] to 4 daNm.

N.B. : This operation transmits the tightening force from the exhaust camshaft dephaser (5) into the lugs of the tool [0109-7B2].

Tighten the new bolt (2).

6. Timing check : Timing

Remove :

- The tool [0197-N / EN-52588]

- The tool [0109-7A]

- The tool [0109-7B]

Slacken the tightening bolts [0109-7B5] of the tools [0109-7B2].

Remove the tools [0109-7B2] from the camshaft dephasers (4) and (5).

Rotate the crankshaft 4 times.

Repeat the operations for checking the setting of the timing.

7. Refitting (If setting correct)

Refit :

- The coil of cylinder N° 3

- The camshaft dephasing solenoid valves

- The oil trap

CAUTION : Perform the operations that are required after reconnecting the ancillaries battery

.

.

CAUTION : In the case of a vehicle with 2 batteries, carry out the specific operations for disconnecting and reconnecting the ancillaries batteries.

Reconnect the ancillaries battery or batteries(depending on equipment).

CAUTION : Reinitialise the engine management ECU ; Using the diagnostic tool.

Diagnostic tool ↦Repair ↦Engine management ECU (CMM_MG1CS051) ↦Repair ↦Repair pack ↦Service action ↦Work on the engine ↦Initialisation after work on the timing belt.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image