Peugeot 308: Checking - adjusting : Play in the reduction box bearings

ESSENTIAL : Observe the safety and cleanliness recommendations

.

.

ESSENTIAL : All personnel carrying out work on a vehicle fitted with traction batteries must have received specific electric vehicle training and be authorised to work on these vehicles(observe the regulations in force in the respective country).

1. Adjustment : INPUT SHAFT

1.1. INPUT SHAFT

N.B. : Measure the dimensions between the bearing outer rings and the reduction gear housing after rotating the measured shaft 10 times.

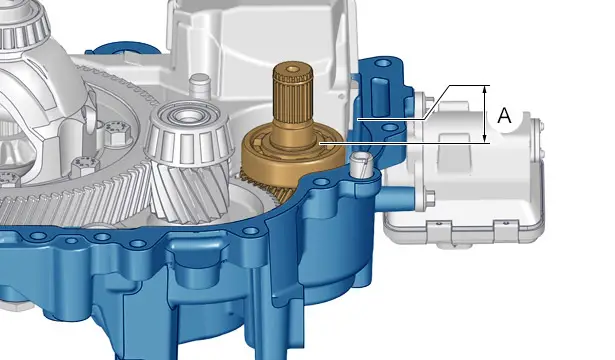

Measure dimension "A" between the input shaft bearing support and the reduction gear housing .

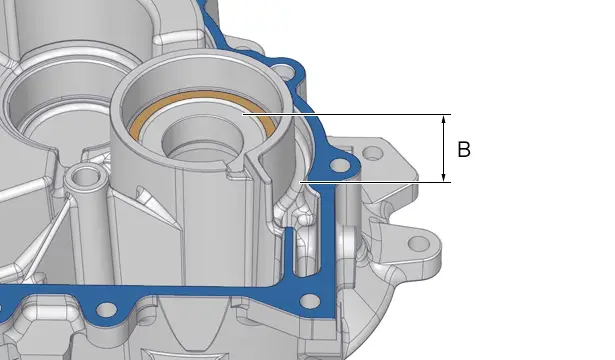

Measure dimension "B" between the input shaft bearing support and the reduction gear housing .

1.2. Calculate the thickness of the adjustment shim

Measure the operating clearance value using the following formula.

Operating clearance value = "A" - "B".

Select the appropriately sized adjustment shim based on the operating clearance value calculated.

N.B. : The operating clearance value of the reduction gear input shaft bearing is between 0,02 and 0,12 mm.

2. Adjustment : Output shaft

2.1. Output shaft

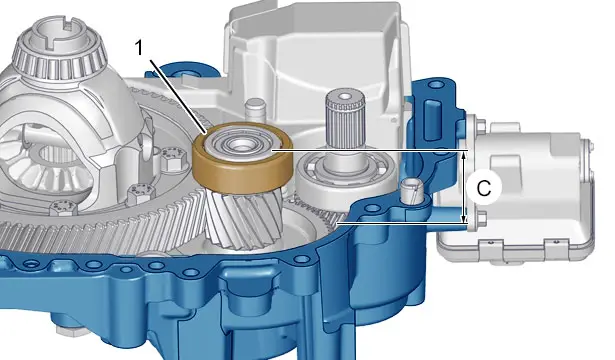

Refit the exterior cage (1) of the bearing on the output shaft .

N.B. : Measure the dimensions between the bearing outer rings and the reduction gear housing after rotating the measured shaft 10 times.

Measure dimension "C" between the output shaft bearing support and the reduction gear housing : Apply a force of 50 N for the measurement.

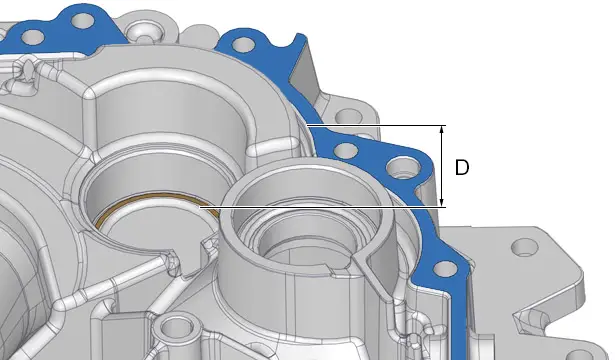

Measure dimension "D" between the output shaft bearing support and the reduction gear housing .

2.2. Calculate the thickness of the adjustment shim

Measure the operating clearance value using the following formula.

Operating clearance value = "C" - "D".

Select the appropriately sized adjustment shim based on the operating clearance value calculated.

N.B. : The operating clearance value of the output shaft bearing is between -0,22 and -0,12 mm.

3. Adjustment : differential

3.1. differential

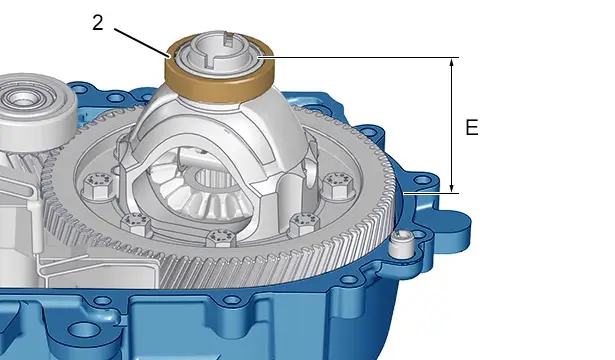

Refit the exterior cage (2) of the bearing on the differential .

N.B. : Measure the dimensions between the bearing outer rings and the reduction gear housing after rotating the measured shaft 10 times.

Measure dimension "E" between the differential bearing support and the reduction gear housing : Apply a force of 50 N for the measurement.

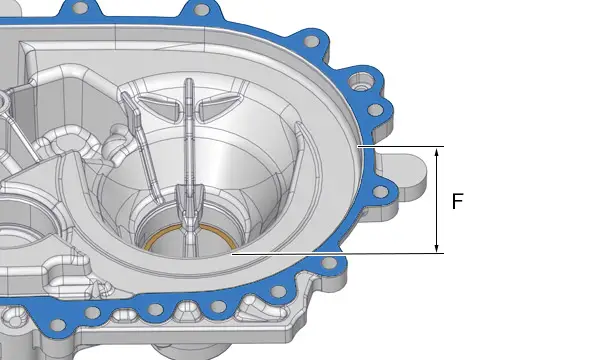

Measure dimension "F" between the differential bearing support and the reduction gear housing .

3.2. Calculate the thickness of the adjustment shim

Measure the operating clearance value using the following formula.

Operating clearance value = "E" - "F".

Select the appropriately sized adjustment shim based on the operating clearance value calculated.

N.B. : The operating clearance value of the differential bearing is between -0,22 and 0,02 mm.

Peugeot 308 2021-2025 (P5) Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image